Micron-Level Separation and High-Precision Filtration: Navector Empowering the High-Quality Development of the Photovoltaic Industry

2025/11/25

In today’s rapidly developing photovoltaic (PV) industry, material quality and manufacturing precision have become key factors in improving the efficiency and reliability of solar cells. As an innovative enterprise in the field of screening technology, Navector is playing an increasingly important role in PV material production with its mature fine powder screening, filtration, and classification technologies.

I. Navector’s Technological Advantages in the Photovoltaic Industry

-

Leading Micron-Level Particle Screening Capability

Navector has long been devoted to the industrial application of precision screening technology, demonstrating outstanding technical strength particularly in the field of PV materials. With its independently developed 1-micron screening capability, using high-density 2000-mesh woven screens as the medium, the company achieves truly production-grade fine powder separation. This structure offers extremely high screening precision while maintaining thorough cleanability, ensuring consistency and purity of particles during continuous production.

-

Patented Silver Paste Filtration Screen Technology

For handling high-viscosity pastes, Navector independently developed the NHCF series silver paste filtration screens, specifically designed for front-side solar silver paste. The equipment adopts German high-viscosity coating filtration technology combined with an ultrasonic vibration system, achieving –8 μm high-precision filtration even under high-solid and normal-pressure conditions.

-

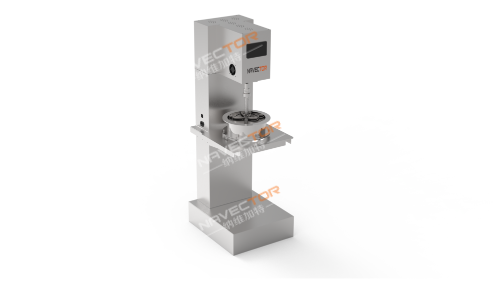

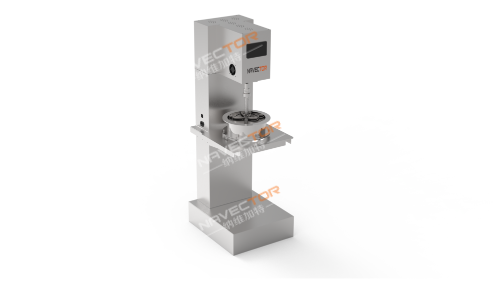

Diversified and Efficient Screening Equipment Portfolio

Navector provides a rich lineup of screening equipment, including but not limited to ultrasonic vibrating screens, NTS series tumbler screens, linear vibrating screens, airflow screens, and more. These can cover various material forms such as dry powders, wet slurries, and ultra-fine particles. By offering customized solutions for different application scenarios, Navector meets the comprehensive requirements of uniform distribution, purity control, and capacity efficiency in PV material production.

II. Specific Application Scenarios of Screening Technology in Photovoltaic Material Production

-

Silver Paste Purification and Filtration

In solar cell manufacturing, the stability and purity of front-side silver paste directly affect printing quality and electrical performance. Navector’s NHCF series filtration screens remove fine particles and impurities, ensuring highly pure and uniformly distributed paste. This significantly reduces printing defect rates and improves line width uniformity and electrical conductivity.

-

Classification of Ultra-Fine Silicon Powder and Additives

PV precursors, dopants, and nano-scale additive materials require extremely high uniformity. Navector’s micron-level screening technology provides precise classification control for these materials, narrowing and stabilizing particle size distribution. This provides a reliable foundation for subsequent processes such as melting, crystal pulling, or slurry preparation, thereby enhancing PV module performance and consistency.

-

Quality Control and Material Recycling

Navector screening equipment can be deployed at key points along the production line to perform real-time screening and rejection of raw materials and intermediates, preventing substandard particles from entering downstream processes. Meanwhile, through online screening of recycled materials (such as process residues, waste slurries, or reclaimed powders), efficient circular utilization can be achieved, reducing production costs and improving resource efficiency.

III. Future Outlook: Technological Integration and Industrial Synergy

-

Enhancing PV Module Efficiency and Reliability

By improving raw material purity and particle distribution consistency, Navector’s screening technology directly contributes to enhanced PV module efficiency. High-quality materials are fundamental to producing high-performance, long-lifespan photovoltaic components.

-

Reducing Manufacturing Risks and Costs

Precise screening reduces the entry of defective materials, lowering scrap rates and rework costs. Additionally, efficient screening of recycled materials helps save raw material costs and improves overall production-line economics.

-

Supporting Green Manufacturing and Sustainable Development

The photovoltaic industry is inherently a green energy industry. Navector emphasizes efficiency, precision, and environmental protection in its technology, reducing material waste and improving yield rates to support PV manufacturers in implementing green manufacturing.

-

Strategic Technological Reserves and International Competitiveness

As the global PV industry advances toward high-end and precision development, Navector—through its core capabilities in ultra-fine powder screening and customized filtration technologies (such as silver paste screening)—provides PV enterprises with differentiated competitive advantages while strengthening its own technological barriers and influence in the international market.

Navector (Shanghai) Screening Technology Co., Ltd., grounded in advanced screening technologies and supported by ultrasonic systems, multiple screening models, and customized solutions, precisely addresses key needs in PV materials regarding purity, particle distribution, and recycling. In the future, we will continue to deepen our presence in the PV field, innovate screening technologies, and provide high-performance, high-reliability, and cost-effective screening solutions to support the green and sustainable development of the renewable energy industry.