Multi-Scenario Application Analysis of the Navector Compact Sieve: A Key Equipment from Raw Material Purification to Production Line Optimization

2025/12/20

In modern industrial production, material screening is a fundamental process to ensure product quality and production safety. Developed based on real industrial site requirements, the Navector NCS Series Compact Sieve is a versatile screening solution. With its high efficiency, flexibility, and low-profile, compact design, it has become an important piece of equipment for many industries seeking to improve production efficiency and quality control.

I. Introduction to the Compact Sieve

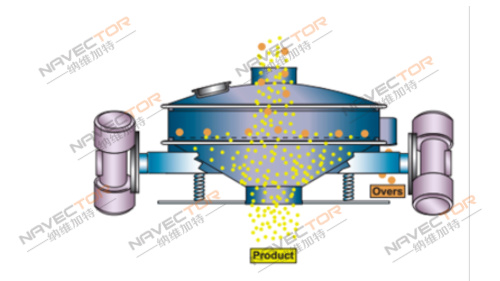

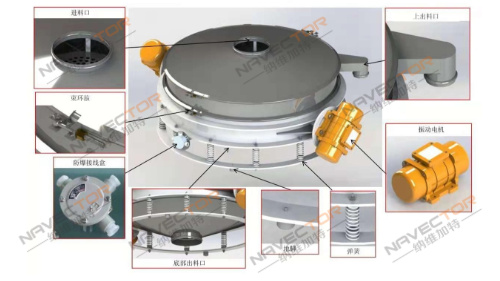

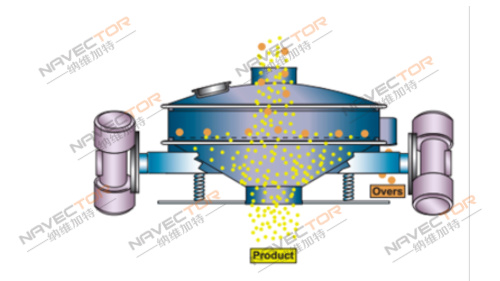

The NCS Series Compact Sieve is a low-profile screening machine. Materials are screened on the mesh surface through compound vibrations generated by vibration motors, while undersize materials are discharged directly downward from the center. This design allows easy integration into production lines while enabling high-capacity processing. The equipment features a compact structure, fully enclosed design, and adjustable screening modes to accommodate different material characteristics and screening objectives.

II. Typical Application Scenarios of the Compact Sieve

-

Food Processing Industry: Raw Material Purification and Safety Control

Food production places extremely high demands on raw material purity. Powdered or granular materials such as flour, starch, seasonings, and dry ingredients may contain foreign contaminants like metal fragments, stones, or agglomerates before feeding. These impurities can affect taste, cause equipment failure, or even lead to food safety incidents.

The NCS Compact Sieve, with adjustable vibration modes and high-precision meshes, effectively removes oversized particles and foreign materials, significantly improving raw material safety and the reliability of downstream equipment. It is an indispensable basic device in food processing lines.

-

Seasonings and Additives Screening: Ensuring Uniformity and Stability

Seasoning powders, flavor enhancers, and certain functional powders require strict particle size uniformity. The compact sieve allows materials to spread evenly on the screen surface, preventing entanglement and facilitating uniform screening and buffered separation. This provides more consistent qualified materials for subsequent mixing, packaging, and other processes.

-

Chemical and Granular Material Classification: High-Precision Screening at High Throughput

In the chemical industry, various granular materials such as catalyst powders and resin pellets require efficient screening and impurity removal. With its large processing capacity and adjustable vibration characteristics, the compact sieve readily adapts to the fine screening requirements of materials with different particle sizes and densities. Its fully enclosed design effectively controls dust and reduces energy consumption, making it an ideal choice for continuous chemical production lines.

-

Metal Powder and Non-Mineral Industries: Impurity Removal and Particle Control

Industries such as metal powders, ceramic powders, and refractory materials also have strict requirements for particle distribution and impurity content. The compact sieve can be configured with optimal vibration modes based on material properties. Through its central direct discharge design, undersize products quickly enter the next production process, while oversized particles and difficult impurities are removed, improving final product precision and process stability.

III. Advantages of the Compact Sieve

Compared with traditional screening equipment, the NCS Series Compact Sieve offers the following significant advantages:

-

Low-profile and compact: Suitable for production lines with limited space, easy to move and integrate into layouts.

-

Fully enclosed structure: Reduces dust emission and noise, meeting clean production requirements.

-

Adjustable screening modes: Dual-motor balanced structure provides greater flexibility and adaptability.

-

Easy cleaning and maintenance: Quick disassembly design with no hygiene dead zones, suitable for frequent mesh replacement.

-

High processing capacity: Central direct discharge design enables higher throughput and smoother material flow.

With its high throughput, adjustable screening modes, and fully enclosed design, the Navector NCS Series Compact Sieve delivers outstanding performance in screening applications across food, chemical, and metal powder industries. It not only effectively ensures raw material quality and production safety, but also integrates seamlessly with production lines to enhance overall efficiency and process stability. As a versatile and highly adaptable screening solution, the compact sieve is an indispensable piece of equipment in modern industrial screening applications.