In the field of industrial screening, improving efficiency and precision has always been the core focus of technological evolution. Navector, as a professional enterprise deeply engaged in globalized screening technology, has achieved a significant breakthrough in screening processes through the development of the NLS series linear vibrating screen.

I.Precise Separation: Meeting Multi-Scenario Needs for Dry Granules and Slurry Materials

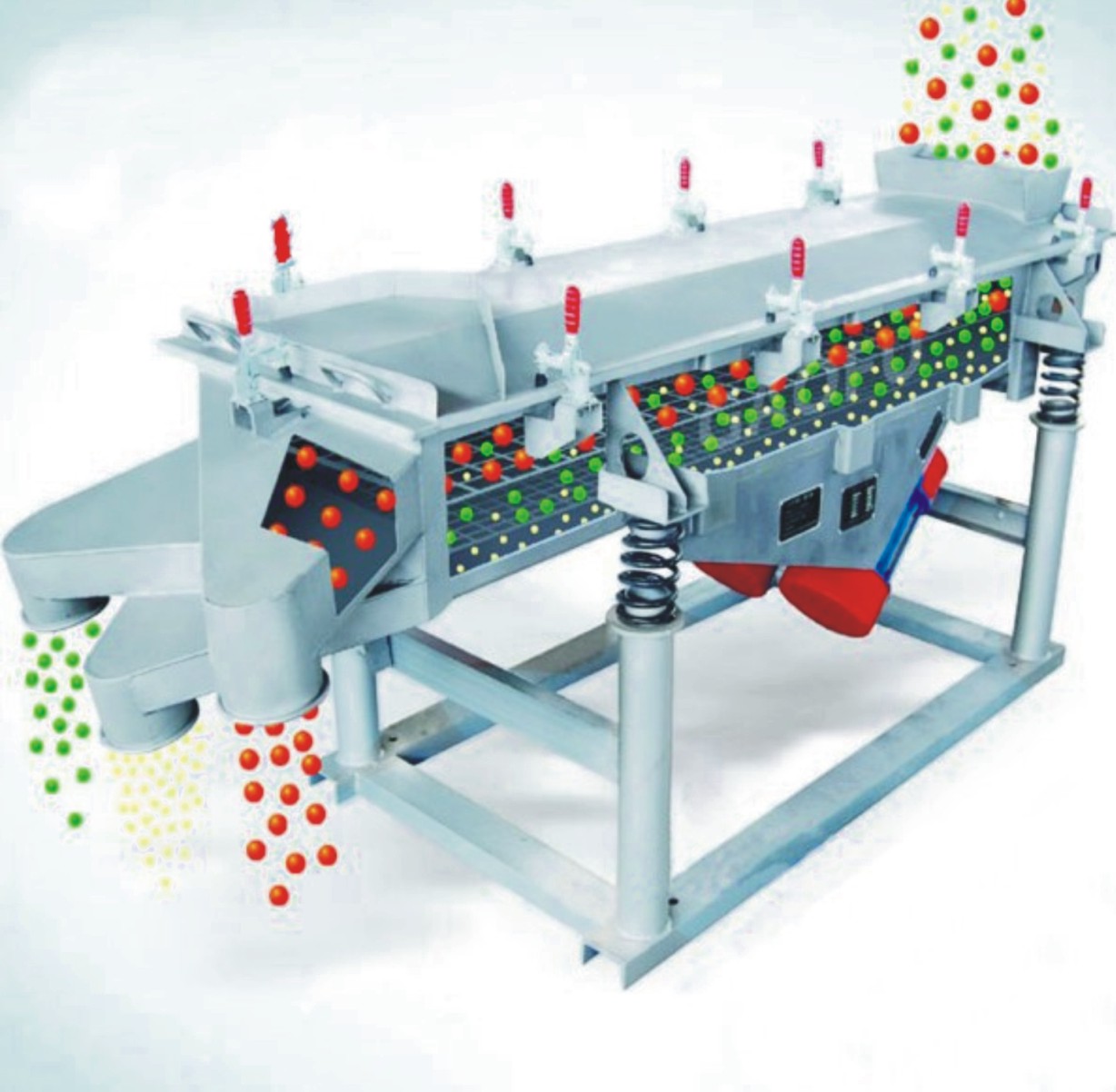

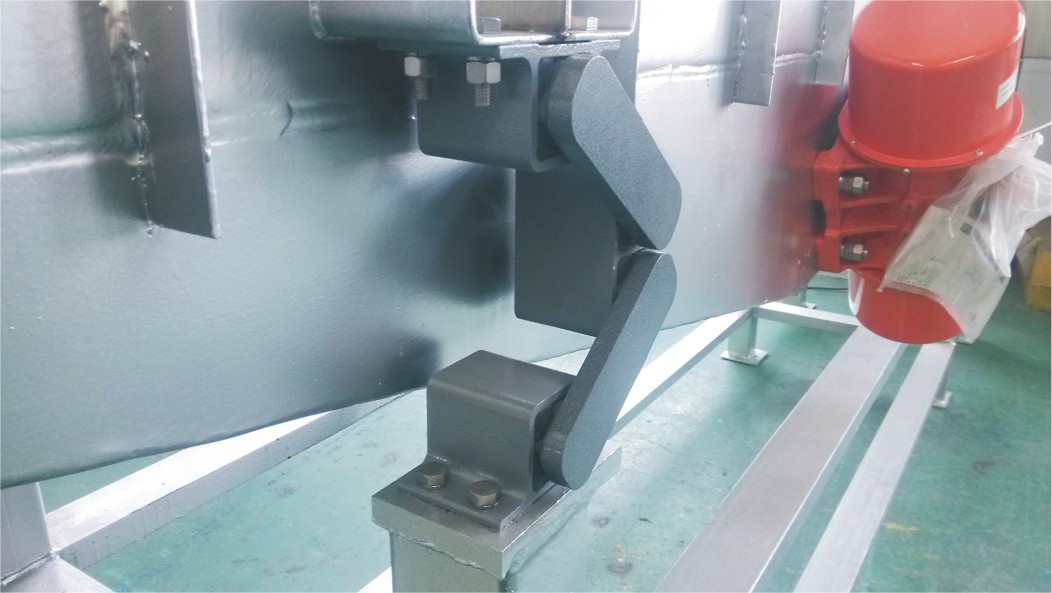

The NLS series has undergone deep optimization and upgrading of the traditional linear screen, particularly with innovative handling of material motion trajectories. By redesigning the vibration reduction system, it no longer relies on ordinary springs but instead adopts a new structure that both absorbs vibration and transmits excitation force. This allows materials to not only follow a parabolic trajectory but also generate planar circular motion, maximizing contact with the screen surface and screening opportunities, thereby achieving efficient separation of dry granules and slurry materials.

Under this power mode, the trajectory of materials on the screen mesh is closer to the mesh and more sustained, resulting in more precise screening. At the same time, the throughput is greatly increased, achieving both high efficiency and high quality.

II.Core Upgrades: Dual Breakthroughs in Low Energy Consumption, High Output, and Easy Maintenance

III. Environmentally Adapted: Fully Enclosed Design with Seamless Production Line Integration

Every optimization of the Navector linear screen stems from precisely addressing the pain points of traditional equipment—transforming from “handling only single materials” to “covering dry granules and slurry,” from “high consumption and low output” to “energy-saving and high-yield,” from “complex maintenance” to “simple and easy maintenance,” from “dust pollution” to “fully enclosed and environmentally friendly,” and from “difficult production line integration” to “automatic collaborative production.” It fully meets enterprise needs in aspects such as separation precision, cost control, maintenance efficiency, environmental compliance, and automation adaptation.