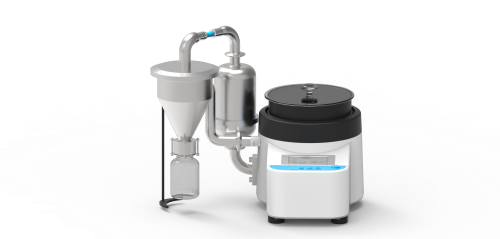

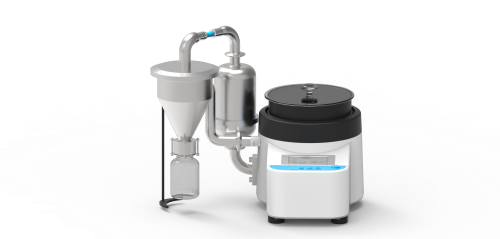

Navector Mini Negative Pressure Airflow Sifter: Prevents Agglomeration, Increases Efficiency, and Offers a Precise Screening Solution

2025/09/23

When processing low-density and easily agglomerated fine particles, electrostatic adsorption, micro-wet adhesiveness, or surface tension often lead to agglomeration. Once agglomerates form, not only does the sample distribution become uneven, but screen holes are frequently blocked, and analytical results can be seriously skewed, with repeatability difficult to ensure. The Navector Mini Negative Pressure Airflow Sifter is specifically designed to address this industry challenge.

Ⅰ. How It Reduces Agglomeration

-

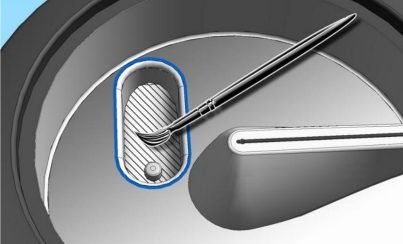

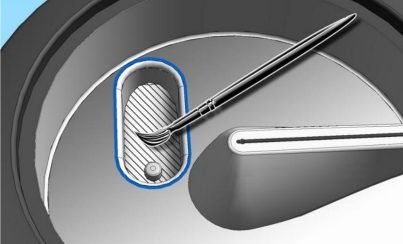

Air Injection + Negative Pressure Combination

The airflow at the nozzle is drawn into the negative pressure environment, accelerating the gas flow towards the surface of the screen and passing through the screen holes. This "blow-suck" airflow pattern continuously applies minor shear forces to the particles, separating loose or initially bonded particles, while reducing the adhesion effects caused by static electricity and humidity.

The intensity of agglomeration varies depending on the material. Some powders only require mild airflow to disperse, while others need stronger airflow to break them apart. However, excessive airflow can lead to particle breakage or damage. The Navector Mini Negative Pressure Airflow Sifter supports adjustable nozzle speeds, allowing users to find the optimal airflow intensity for their material, thereby minimizing agglomeration while maintaining particle integrity.

-

Screen Purification and Anti-Blocking Design

Airflow not only disperses the particles but also blows across the screen surface, promoting cleaning of the screen holes and reducing screen clogging caused by agglomerates collecting above the screen. This dual action stabilizes the screening process and ensures more reliable results.

Ⅱ. Specific Benefits of Reduced Agglomeration

-

Lower Sample Loss: Agglomeration or particle adhesion can cause many fine particles that should pass through the screen holes to be trapped or broken. Airflow dispersion helps prevent such losses.

-

Extended Screen Life: Fewer blockages → reduced cleaning frequency → slower screen wear, saving on maintenance costs.

-

Faster Operation: With reduced agglomeration, the time required to pass through the screen holes becomes more stable and shorter, with fewer interferences from auxiliary factors, keeping the overall screening time within a stable range.

The Navector Mini Negative Pressure Airflow Sifter propels ultrafine powder screening technology into the era of "precise control." Its unique airflow screening technology not only solves the agglomeration problem of low-density particles but also tackles the industry’s long-standing issue of screen clogging with its innovative self-cleaning screen system, offering comprehensive solutions from R&D to mass production in industries such as pharmaceuticals, chemicals, and food.