Ⅰ. Analysis of Frequent Screen Mesh Replacement

In the handling of industrial powders and granular materials, the lifespan of screening equipment’s mesh is one of the key factors affecting production efficiency and operating costs. Traditional vibrating screens often encounter issues such as mesh wear, clogged apertures, or breakage during screening, especially when processing high-hardness, easily agglomerating, or wet materials. These problems lead to frequent mesh replacement, increasing equipment downtime and maintenance costs, and potentially affecting particle size consistency and product quality.

Navector swing screens have undergone systematic engineering optimization during the design phase to address these issues. Their mesh lifespan extension technology focuses on three main areas: vibration mode optimization, mesh structure reinforcement, and mesh cleaning mechanisms.

Ⅱ. Core Mechanism of Navector Swing Screen Technology

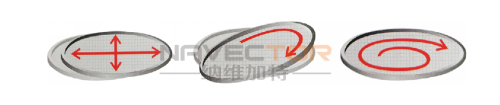

Navector swing screens use an elliptical swinging motion instead of traditional linear or circular vibrations, causing the material to roll back and forth in a wave-like trajectory across the screen surface. This vibration mode disperses materials evenly over the entire mesh, reducing localized impact and wear. At the same time, the swinging motion maintains low amplitude and high frequency, distributing cyclic stress evenly on the mesh and thereby reducing the risk of fatigue fracture.

Ⅲ. Advantages of Swing Screens in the Screening Process

The swinging motion reduces areas of concentrated impact from the material, distributing stress more evenly across the mesh and lowering the likelihood of fatigue fractures. This is especially effective for screening high-hardness particles and metal powders.

The combination of elastic cleaning balls and external vibration keeps the mesh apertures clean, preventing damage caused by clogging. This is particularly beneficial when screening wet powders or agglomerating materials.

With adjustable vibration parameters and selectable mesh materials, Navector swing screens can optimize screening for materials with varying hardness, particle size, and moisture content, ensuring stable operation across diverse conditions.

Ⅳ. Application Areas

Suitable for screening resins, coatings, pigments, rubber powder, carbon black, and auxiliary solvents. Swing screens handle high-hardness and sticky materials, maintaining long-term mesh operation.

Can screen powdered sugar, milk powder, starch, juice solids, and dehydrated vegetables. The elastic cleaning mechanism prevents clogging by wet or caking materials, ensuring continuous production.

Used for precision screening of traditional Chinese medicine powders, Western medicine powders, and pharmaceutical raw powders. Maintains long-term aperture stability, reducing micro-particle blockage and cross-contamination risks.

During screening of high-hardness metal powders, oxides, and foundry sand, the uniform stress distribution and cleaning mechanism significantly reduce mesh damage and enhance continuous production capacity.

In wastewater treatment, solid waste recovery, and specialty powder classification, swing screens extend mesh lifespan while maintaining screening efficiency, suitable for continuous operation under diverse conditions.

Navector swing screens achieve extended mesh lifespan and reduced maintenance costs through vibration mode optimization, multi-layer mother-daughter mesh structures, and cleaning mechanism design. Their technical core lies in uniform stress distribution, clogging reduction, and adaptability to complex material properties. This technology applies across chemical, food, pharmaceutical, metallurgy, and environmental industries, providing engineers with a reference solution for mesh selection, maintenance management, and process optimization. In practice, vibration amplitude, frequency, and cleaning system parameters can be adjusted according to material characteristics to maximize mesh service life.