When Should the Screen Mesh Be Replaced? Navector Shows You How to Judge Accurately

2025/11/24

In the daily operation of screening equipment, the screen mesh, as a core component, directly determines screening efficiency, product quality, and equipment lifespan. Once the screen mesh is damaged or its performance declines and is not replaced in time, a series of problems may arise: reduced capacity, lower screening accuracy, and increased energy consumption; in severe cases, material back-mixing and abnormal equipment vibration may also occur.

I. Hazards of Not Replacing the Screen Mesh in Time

-

Decline in screening efficiency: When the screen mesh is worn, its apertures become larger or deformed, causing a reduction in screening accuracy. Materials that should have been intercepted or classified may pass through, resulting in out-of-spec particle size and serious impacts on production efficiency.

-

Increase in return material rate and loss of capacity: Aging or damaged screen meshes may cause undersized product to mix with nonconforming particles, increasing the return material rate and operating costs. At the same time, to maintain output, more frequent re-screening or manual intervention may be required.

-

Mechanical damage to equipment: A damaged or loose screen mesh may cause uneven vibration and bouncing during operation, increasing the machine’s vibration amplitude. Over time, this can lead to excessive wear on the housing, vibrating parts, and support structures.

-

Difficulty in cleaning and increased maintenance costs: As the screen mesh remains in use for longer periods, apertures may become blocked by material. Repeated clogging of an aging screen mesh not only reduces screening efficiency but also requires more frequent shutdowns for cleaning, which may accelerate further damage.

-

Critical product quality risks: In industries with strict particle-size requirements (such as lithium battery powders, 3D printing metal powders, pharmaceuticals, chemicals, etc.), particle-size deviations caused by mesh aging may affect downstream product performance and pose significant commercial risks.

II. Scientific Criteria for Determining When a Screen Mesh Needs Replacement

-

Visual structural inspection

When the equipment is shut down, remove the screen mesh and inspect its appearance carefully. Check for broken wires, damaged apertures, cracks, warped edges, or loosened hooks. If these issues are present, the mesh may no longer withstand screening stresses.

-

Monitoring screening performance

By comparing key indicators before and after mesh replacement—such as output, particle-size distribution, return rate, and pass rate—evaluate whether screening performance has declined. If undersized product becomes coarser, the pass rate drops, or return material increases significantly, the mesh may be worn or its aperture size has become unstable.

-

Evaluation of cleaning frequency

Record how often the mesh needs cleaning. If shutdowns for cleaning become more frequent due to blocked apertures or material buildup, this may indicate aperture damage, deformation, or clogging, and could signal severe mesh aging.

-

Vibration and noise monitoring

During operation, use vibration monitoring instruments or observe vibration behavior and noise based on experience. If the machine’s vibration amplitude is greater than normal, edges bounce noticeably, or abnormal metal friction sounds occur, the mesh may be loose, structurally unstable, or not fitting properly with the machine.

-

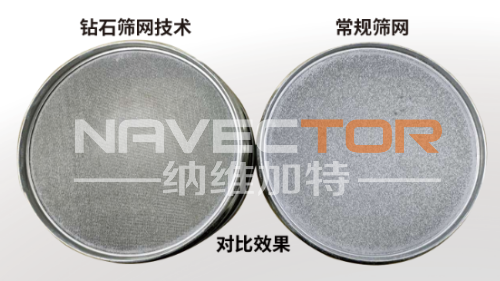

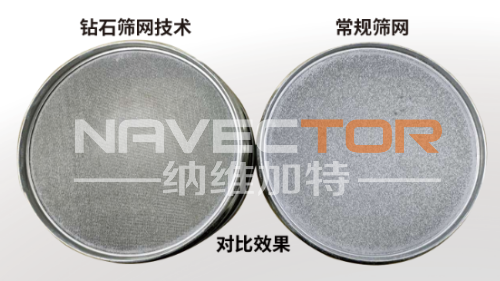

Aperture precision measurement

Use a microscope, magnifier, or specialized measurement tools to check aperture size. If apertures are enlarged, deformed, or irregular, resulting in loss of original screening accuracy, the mesh should be replaced even if structural damage is not visible.

III. Navector Screen Mesh Technology Overview

-

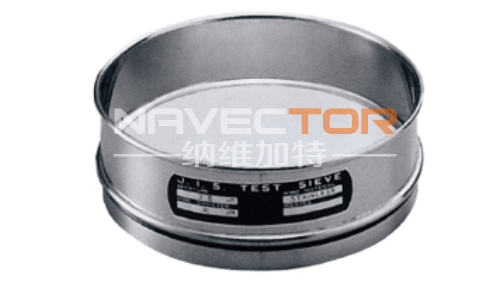

Diverse screening equipment types

Navector provides multiple types of screening equipment, including ultrasonic vibrating screens, tumbler screens, and lithium industry–specific small-particle screening machines, covering applications from basic grading to high-precision screening.

-

High-precision mesh and advanced cleaning systems

The company can customize high-quality stainless-steel meshes based on customer needs, with extremely fine aperture sizes suitable for precision classification. To prevent mesh blockage, multiple cleaning technologies are used, such as bouncing balls and ultrasonic systems. Especially the UCS (Ultrasonic High-Energy) system enhances screening efficiency and extends mesh lifespan by superimposing ultrasonic vibration onto the screen surface.

-

Customized design capability

Navector has strong customized design capabilities. According to specific material characteristics (such as particle-size distribution, density, agglomeration behavior, electrostatic properties, etc.) and production-line requirements, the company designs the optimal mesh structure and screening system for efficient and stable screening.

-

Global service and technical support

Since its establishment in 2005, Navector has built sales and service networks across many countries and regions. In addition to supplying screening equipment, the company provides screen-mesh replacement, spare parts supply, and technical maintenance, delivering reliable long-term support.

Although the screen mesh is only a “component” of screening equipment, its condition determines the efficiency, quality, and reliability of the entire screening process. As a global provider of screening technology and engineering solutions, Navector always takes “full-process operational support” as its core philosophy, offering systematic support in product design, spare parts supply, and maintenance services—helping enterprises reduce operating costs and enhance production continuity.