In fine screening and high-demand classification conditions, screening efficiency is a core indicator for evaluating screening equipment performance. Especially under conditions involving medium-to-fine particles, materials prone to agglomeration, or high-throughput continuous production, traditional vibrating screens often suffer from efficiency fluctuations and insufficient screening.

The NTS series gyratory screen launched by Navector (Shanghai) Screening Technology Co., Ltd. has demonstrated stable screening efficiencies of 95%–99% across multiple industrial applications. This performance is not achieved by enhancing a single parameter, but rather through systematic optimization based on screening physics, particle motion behavior, and engineering structural design.

I. What Is the Essence of Screening Efficiency?

II. Core Principle of the NTS Series Gyratory Screen: Simulating Manual Screening

The NTS series gyratory screen mechanically recreates the behavior of manual screening through engineered structures.

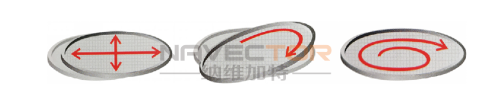

Planar gyratory motion: allowing particles to “walk on the screen” rather than “jump on the screen.”

The NTS series adopts low-speed, long-stroke planar gyratory motion. The screen box moves along an approximately elliptical or circular trajectory within the horizontal plane, causing the material on the screen surface to exhibit:

III. High Screen Surface Utilization Is the Basis for High Efficiency

IV. Full Stratification Is a Key Condition for High-Efficiency Screening

Before screening, particle stratification must first be completed. The prerequisite for effective screening is that fine particles can smoothly settle to the screen surface.

Through low-acceleration planar motion, the NTS series gyratory screen enables the material on the screen surface to naturally form:

upper layer: coarse particles,

middle layer: near-size particles,

lower layer: fine particles.

This stratification mode is more stable and less easily disrupted, allowing fine particles to continuously contact the apertures and complete the screening process.

V. Longer Residence Time Creates More Screening Opportunities

VI. Engineering Structure Ensures Long-Term Efficiency Stability

VII. High-Efficiency Application Scenarios for the NTS Series Gyratory Screen

The NTS series gyratory screen is particularly suitable for the following operating conditions:

precise classification of medium-to-fine particles,

high-throughput continuous production,

process stages with stringent requirements for screening consistency,

production lines that do not allow fluctuations in screening yield.

Therefore, it is widely used in fine chemicals, metal powders, new energy materials, food, and functional powder industries.

Conclusion: 95%–99% Efficiency Comes from Systematic Design

The ability of the NTS series gyratory screen to achieve 95%–99% screening efficiency does not rely on higher amplitude or frequency, but is based on:

planar gyratory motion that aligns more closely with the physical principles of screening, higher screen surface utilization, more thorough and stable particle stratification, and mature, reliable engineered structural design.

Within Navector’s screening technology system, the NTS series gyratory screen is a professional screening solution oriented toward high efficiency and high consistency.