Food production places extremely high demands on raw material purity and safety. The screening stage directly affects finished product quality and production line stability. Navector direct discharge screens are designed to address the specific needs of the food industry and provide efficient solutions.

The food industry imposes strict requirements on raw material purity and production stability. Food raw materials such as flour, starch, sugars, and seasonings must have foreign matter, agglomerates, and unqualified particles removed before entering the production process to ensure food safety and product quality. Navector direct discharge screens are specifically designed for direct material discharge. Screened materials are discharged downward through the center, allowing easy connection to food production lines and suitability for continuous production modes.

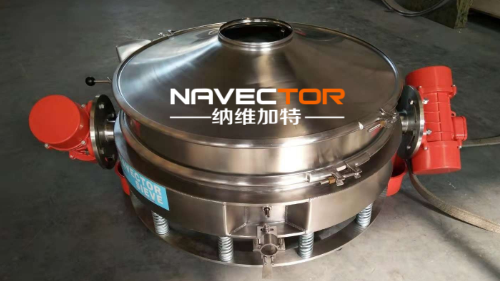

Direct discharge screens are low-profile screening equipment with a small footprint and compact structure. This design facilitates installation in limited spaces at food production sites and allows flexible configuration according to production line layouts. The equipment adopts a fully enclosed structure, effectively reducing dust leakage and minimizing the risk of environmental pollution. Both the interior and exterior of the screen are easy to clean, meet food-grade hygiene standards, and help reduce the risk of cross-contamination.

The direct discharge screen adopts an optimized dual-motor balanced structure, and the screening mode can be adjusted according to material characteristics, enabling the equipment to meet the screening requirements of various food raw materials. The multi-directional forces generated by vibration promote uniform material screening while effectively separating large foreign particles, improving raw material purity. The stable output of screened material is conducive to the smooth operation of downstream processes on the production line.

Food production sites have clear requirements for equipment operational stability and ease of maintenance. Navector direct discharge screens feature a rational structural design and convenient disassembly, allowing rapid cleaning of the screen mesh and internal components. The equipment has no sanitary dead zones and is easy to maintain and inspect, which is of great significance for ensuring long-term stable operation.

In practical applications, direct discharge screens are mainly used in food production processes to remove hard foreign matter and impurities from raw materials, prevent production accidents, and enhance the stability of final product quality. Such equipment plays a key role in flour processing, starch handling, seasoning production, and other processes, improving production efficiency and food safety control capabilities.

Based on mature screening technology and a rational structural design, Navector direct discharge screens meet the comprehensive requirements of the food industry for clean, hygienic, and efficient screening. The equipment demonstrates clear advantages in ensuring raw material quality, improving production efficiency, and reducing operating costs, providing strong equipment support for stable food production.