Due to the diversity of material characteristics and varying capacity requirements, selecting screening equipment with appropriate technology matching and reliable operation is critical to achieving production objectives and improving economic efficiency. Since its establishment in 2005, Navector (Shanghai) Screening Technology Co., Ltd. has focused on the research and development of screening technologies, providing systematic and customized screening solutions for multiple industries.

I. Define Screening Requirements

The selection of screening equipment should be based on production objectives and material characteristics. Different materials vary in particle size, bulk density, shape, and moisture content, and factors such as agglomeration tendency and static electricity generation can all affect screening efficiency. Selecting screening technology that matches specific material properties and process requirements is the key to achieving efficient production. Navector’s product portfolio covers screening equipment ranging from conventional granules to difficult-to-screen micron-level materials, meeting the screening needs of various industries.

II. Evaluate Key Performance Indicators

Appropriate screening accuracy ensures particle size consistency and improves downstream process performance. Screening accuracy is influenced by factors such as mesh aperture, vibration mode, and screen surface design. For example, the Navector NTS series tumbler screen features a large screening area and high-precision separation capability, and can be equipped with an ultrasonic mesh cleaning system, making it suitable for high-throughput, fine screening of difficult materials.

High-capacity screening equipment helps maintain stable production rhythms and prevents the screening process from becoming a bottleneck in the production line. The effective screening area, vibration frequency, and structural design directly affect the throughput per unit time. Proper evaluation of these indicators helps select screening equipment that matches production scale and improves overall production efficiency.

III. Consider On-Site Adaptability

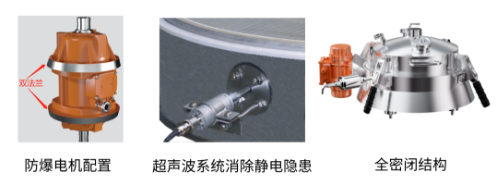

The operating environment has a direct impact on equipment suitability. Dust, static electricity, and flammable or explosive conditions are common safety risks in industrial screening, and equipment used in such environments must feature reliable protective designs. Through enclosed structures, compliant explosion-proof components, and static control measures, Navector products effectively enhance operational safety under complex on-site conditions.

Ease of maintenance is equally critical. The convenience of screen replacement, rationality of cleaning procedures, and simplicity of daily maintenance are all key on-site considerations. Screening equipment with compact structures and easy disassembly can reduce maintenance time and minimize the impact of production line downtime on capacity.

IV. Integrate Typical Application Scenarios

For precision screening requirements in high-end manufacturing, Navector offers a variety of specialized screening solutions.

Navector airflow sieves are suitable for lightweight, easily agglomerated materials, achieving efficient screening through airflow-driven operation and improving both efficiency and stability.

The 3D printing additive recycling system developed by Navector is applied to metal powder recovery in additive manufacturing. Through a fully enclosed inert gas circulation system, it enables powder separation and reuse, significantly improving raw material utilization while controlling oxidation and contamination risks.

Scientific screening not only affects product quality but also has a significant impact on production efficiency, energy consumption performance, and environmental compliance. It is an important component of production process optimization and industrial intelligent upgrading.

Navector consistently places technological innovation and customer value at the core of its strategy, continuously advancing screening equipment R&D and optimizing industry application solutions. The company is committed to meeting the fine screening requirements of various materials across industries and providing reliable assurance for efficient and stable production.