In the face of increasingly strict environmental regulations and the dual carbon strategic goals, every aspect of industrial production is under urgent pressure to upgrade to more sustainable and environmentally-friendly processes. Screening, as a critical process in material handling, has become a key point for companies to achieve compliant production and sustainable development. The dust control and energy efficiency improvements during the screening process are vital for this goal. Navector (Shanghai) Screening Technology Co., Ltd., with its global expertise and technological accumulation, adheres to the principles of innovation and green development. The company is committed to providing high-efficiency and environmentally-friendly screening solutions across various industries, helping companies achieve the dual objectives of emission reduction and efficiency improvement.

Currently, environmental policies are shifting from end-of-pipe management to full-process and detailed management. For example, in many regions, new comprehensive air pollution control plans for the chemical industry have been introduced, which not only strictly limit the concentration of organized emissions but also emphasize stricter control over unorganized dust emissions. These regulations clearly require dust-generating processes such as crushing, screening, and conveying to be carried out in enclosed spaces with efficient dust collection and treatment facilities.

This presents a direct challenge to traditional screening models: the dust dispersion caused by open operations needs to be resolved, and the energy consumption and screening efficiency of the equipment are directly related to operational costs and emission reduction performance.

Many traditional screening devices have low energy efficiency, resulting in significant energy waste during production. Under new environmental regulations, companies must further reduce energy consumption to meet these requirements, or they will face high energy costs and potential penalties.

In industries such as powder processing and chemicals, the screening process often generates dust, making dust pollution a significant factor affecting environmental quality. Effectively preventing dust leakage and ensuring that emissions comply with new regulations is another major challenge for companies.

The limitations in precision and efficiency of traditional screening devices often lead to incomplete screening and improper waste treatment, resulting in resource waste and environmental pollution. This not only affects product quality but also increases the cost of waste treatment for companies.

In response to the increasingly strict environmental regulations, Navector (Shanghai) Screening Technology Co., Ltd. provides a series of high-performance, low-energy consumption, and environmentally friendly screening solutions through continuous innovation and technology optimization.

Navector's products adopt a fully enclosed structure design to physically prevent the escape of dust during the production process, ensuring compliance with environmental emission standards. Especially in high-dust emission industries such as chemicals, Navector’s equipment optimizes the sealing design to ensure that the dust concentration in the working environment is consistently below national standards, fundamentally addressing the environmental risks in the screening process.

Powder Leak Prevention Design

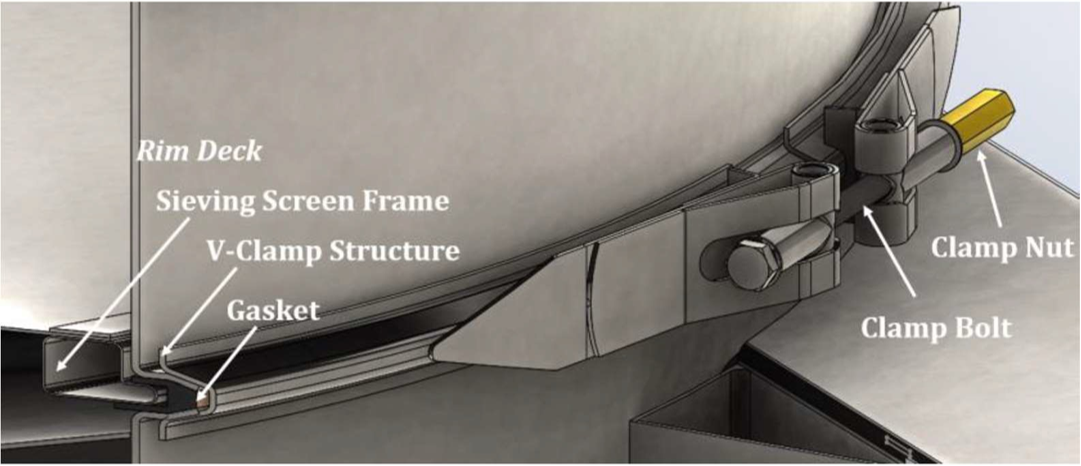

We have considered the powder leak prevention design in the V-type clamp:

The tighter the clamp, the better it prevents vibration and movement of the mesh frame, thus preventing powder leakage.

The sealing ring is made of silicone rubber: enhancing durability and sealing performance.

Unique design of the frame structure.

Water Leak Test

To solve the common industry problem of fine powder materials blocking mesh openings and reducing efficiency, Navector’s advanced technologies, such as ultrasonic mesh cleaning systems, effectively prevent the adhesion and clogging of fine materials, significantly improving screening efficiency and processing capacity. This reduces the frequency of downtime for cleaning, enhances continuous production capabilities, and reduces secondary pollution and energy waste caused by repeated starts and manual cleaning.

Photo of small particles after screening, upper part of the screen mesh.

No agglomeration was found, the ultrafine powder effect is perfect.

Navector’s screening equipment is also equipped with an advanced intelligent monitoring system that can monitor key data in real time during the screening process, including equipment operation status, energy consumption, and emission data. This data helps companies optimize screening processes, promptly identify and solve problems, and ensure that production meets the requirements of new environmental regulations.

As environmental requirements continue to rise, future screening technologies will continue to develop in the direction of greater efficiency, intelligence, and environmental friendliness. Navector will continue to keep up with industry trends and advance the innovation of screening technology, helping companies achieve green development in the global environmental context.

On one hand, equipment will no longer be standalone units, but intelligent nodes that can be integrated into digital management platforms, enabling real-time monitoring and optimization of operational status, energy consumption, and emission data. This will provide data support for lean production and precise environmental management.

On the other hand, as the circular economy and the construction of "zero-waste cities" progress, the application of screening technology in resource recovery and fine sorting of solid waste will become increasingly important. Navector will continue to focus on the research and development of high-precision, customized screening technologies, aiming to provide specialized solutions for new strategic emerging fields such as new energy materials and resource recovery, helping to build a resource-saving, environmentally friendly modern industrial system.

With the promotion of new environmental regulations, the efficiency and environmental friendliness of screening equipment have become core competitive advantages for enterprises. With its innovative technological solutions and high-quality equipment, Navector helps companies effectively tackle environmental challenges and achieve emission reduction and efficiency improvement. In the future, as screening technology continues to advance, Navector will continue to provide more efficient, intelligent, and environmentally friendly screening solutions for various industries, contributing to the global green transformation and sustainable development of industries.