From Shanghai’s Minhang District to the global market, Navector’s international journey exemplifies the leap from “Made in China” to “Created in China.”

Globalization, for China’s manufacturing industry, is not only an inevitable choice for market expansion but also a crucial path toward technological iteration and brand upgrading. As an innovative enterprise in the field of screening technology, Navector has, since its founding in 2005, abandoned the model of competing solely on cost and instead chosen a path of globalization driven by technological innovation.

China’s manufacturing industry is shifting from price advantages to technological advantages. Navector’s globalization journey demonstrates the viable path through which China’s specialized and innovative enterprises can open the global market with core technology.

In today’s deeply integrated global industrial chain, “going global” is no longer an option but a necessity for Chinese manufacturing. As the domestic market gradually reaches saturation, more and more Chinese enterprises are realizing that internationalization is the only way to enhance competitiveness and expand market share. Exporting not only helps companies break through domestic market bottlenecks but also improves production efficiency, drives technological innovation, and promotes product upgrades through the diverse demands of international markets.

For Navector, globalization is one of the core driving forces of the company’s development. By establishing a global presence, Navector not only provides localized services to international customers but also leverages diverse global market needs to continuously improve its technology and products, thereby enhancing its global competitiveness.

From its Shanghai headquarters to the Chengdu R&D center, from its domestic sales network to overseas branches, Navector’s globalization journey has always been supported by strong corporate capabilities and a rich product portfolio.

As a company focused on screening technology, Navector has become a trusted equipment supplier across multiple industries through its global layout and localized service capacity—widely serving new materials, 3D printing, new energy, food, pharmaceuticals, chemicals, and metallurgy sectors.

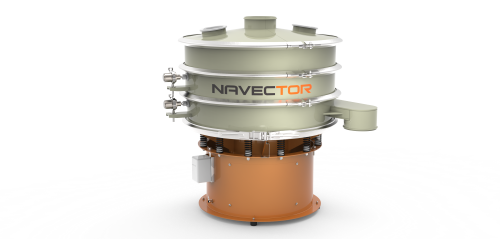

In terms of products, Navector continues to overcome technological bottlenecks and launch a range of industry-leading solutions. Its main products include ultrasonic vibrating screens, tumbler screens, ultrasonic tumbler screens, rotary vibrating screens, circular rotary screens, and 3D printing screening machines, all of which are applied worldwide.

In the new energy sector, Navector has developed a fine particle screening system specifically for the lithium battery industry to meet high-precision, high-efficiency screening requirements.

In the 3D printing field, Navector’s 3D printing additive recycling system not only improves the screening precision of metal powders but also enables powder recovery and reuse, effectively reducing production costs.

Moreover, Navector is committed to providing comprehensive screening solutions, integrating screening, filtration, conveying, and dust removal systems into a unified service framework to help customers achieve more efficient and precise particle separation.

The NHI series vibrating screen is capable of screening and filtering various materials, whether heavy or light powders, coarse or fine particles, wet or dry substances, slurries, or liquids.

The Navector fine particle screening machine for lithium battery materials is specially designed for the lithium industry. It adopts advanced ultrasonic screening technology and a 3D vibration + tumbler motion mode to effectively prevent mesh blockage and particle embedding, significantly extending screen life and increasing screening capacity.

As a model of Chinese manufacturing, Navector has enhanced its market competitiveness through global expansion and promoted the worldwide development of screening technology.

In the future, Navector will continue to deepen its global strategy, leveraging advanced technology, high-quality products, and a comprehensive service network to provide more efficient and environmentally friendly screening solutions to customers around the world—striving to become a world-class industrial screening company driven by technology and committed to green development.