In the biopharmaceutical industry, microspheres serve as critical intermediates such as drug carriers, vaccine delivery materials, and support materials for regenerative medicine. Their particle size uniformity, purity, and sterility are crucial to the safety and efficacy of downstream formulations. As pharmaceutical standards continue to become more stringent, traditional screening methods have become increasingly unable to meet the industry’s demands for high standards, high consistency, and high-efficiency production.

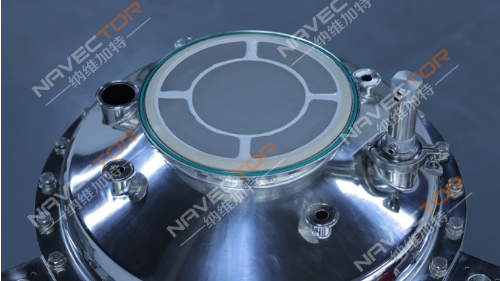

Against this backdrop, the PV Series sterile vibratory microsphere screen independently developed by Navector successfully breaks through technical barriers with its innovative design, providing an advanced and reliable solution for microsphere preparation and screening.

In pharmaceutical microsphere screening processes, companies generally face the following core challenges:

To systematically address these challenges, the Navector PV Series sterile vibratory microsphere screen is built around innovative design, forming a comprehensive, high-standard solution.

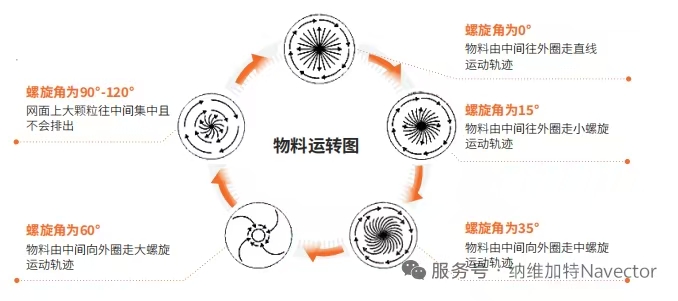

Unique screen structure and vibratory drying technology: Through patented screen structures and vibratory drying technology, microspheres remain highly uniformly distributed during screening, improving particle consistency and screening efficiency.

Fully automatic control system: The screening process supports fully automated control including start-up, operation, cleaning, and shutdown, significantly reducing operator workload and improving production stability.

CIP (Clean-In-Place) and SIP (Sterilize-In-Place) support: Fully enclosed equipment design with online cleaning and sterilization capabilities ensures sterility throughout the entire process and meets GMP and high hygiene requirements of the pharmaceutical industry.

Compliance with ASME-BPE standards: The equipment is manufactured according to stringent pharmaceutical hygiene design standards, featuring a dead-corner-free and fully enclosed structure to effectively ensure production safety and product quality.

Controllable screening precision: With a highly mature screen manufacturing process, customized screens can be provided according to different customer requirements. Screens with precision ranging from 10 μm to 600 μm are available, meeting diverse microsphere needs from nano-scale to medium particle sizes.

Compatibility with both dry and wet processing: Whether the material is in wet suspension or dry powder form, the equipment delivers stable screening performance.

Scientific structural design: Rational frame structure and durable screens ensure low wear during long-term operation.

Quick screen replacement (3–5 minutes): Simplifies maintenance procedures and reduces downtime, lowering labor costs.

Microsphere screens are mainly used for high-precision separation and drying of microsphere materials under sterile conditions, particularly in pharmaceutical and related R&D and production processes.

From supporting cutting-edge laboratory research to ensuring the stable operation of large-scale production lines, the PV Series sterile vibratory microsphere screen demonstrates outstanding performance, proving itself to be an ideal choice for critical screening and filtration processes in pharmaceutical engineering.

Navector will continue to uphold its spirit of innovation, committed to delivering more breakthrough solutions for the global biopharmaceutical industry and driving the entire sector toward higher quality and higher standards.