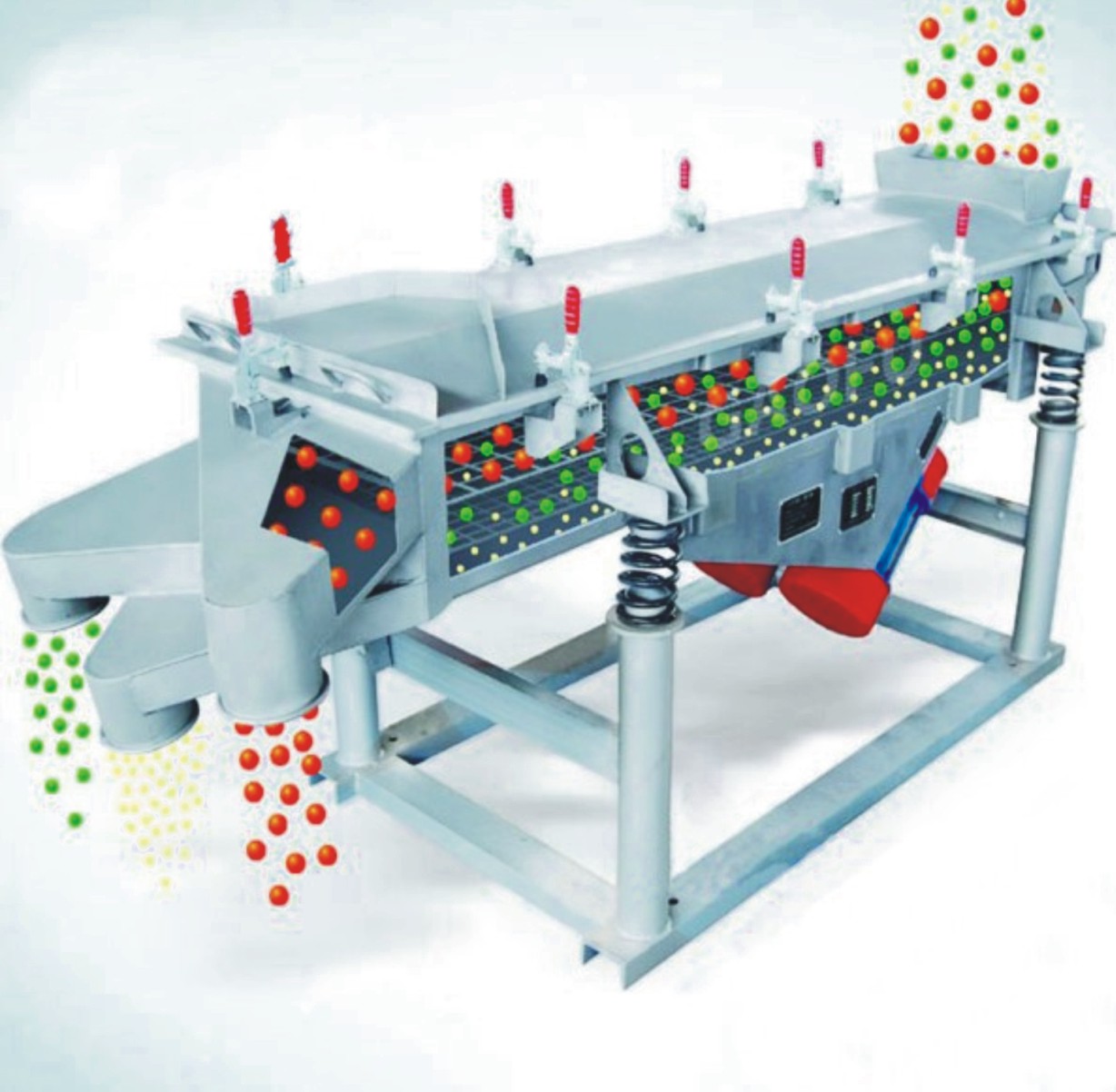

NLS series linear vibrating screen machine developed and produced by Navector is optimised and upgraded to the traditional linear screen, which is capable of separating general materials, including dry particles, slurry-containing materials, with low energy consumption, high output, simple structure, easy maintenance, fully enclosed structure, no dust overflow, automatic discharge, and suitable for assembly line operation.

I. The working principle

Navector engineers have redesigned the vibration damping device, no longer using coil springs or even rubber springs, the new damping device can not only dampen the vibration, but also transfer the excitation force, optimise the vibration curve, so that the material's trajectory in addition to the forward parabola, there is also the plane of the circular motion, greatly increasing the screening capacity and screening accuracy.

II.The advantages of the equipment

The material is closer to the mesh surface, rather than completely thrown forward

The noise is greatly reduced compared with the general linear screen

The material in the mesh travels longer

The screen is easier to tension, and the life is longer

There is a reasonable and effective mesh clearing device

III. Parameters

|

Material size |

0.074 - 10 mm |

|

Mesh material |

Stainless steel 304/316 |

|

Inclination angle |

1° - 7° |

|

Number of layers |

1 - 2 |

|

Dimensions |

500 mm x 2000 mm 500 mm x 2500 mm 500 mm x 3000 mm 1000 mm x 2000 mm 1000 mm x 2500 mm 1000 mm x 3000 mm mm |

|

Voltage |

3 phase, 380 V, 50 Hz or customised power supply |

|

Power |

2 x (0.4 kw - 1.5 kw) |

|

Material |

304 stainless steel or carbon steel |

IV. Applications

Used in chemicals, food, ceramics, pharmaceuticals, minerals, plastics, metallurgy, grain and more, its productivity and durability are well proven.