I. Introduction:

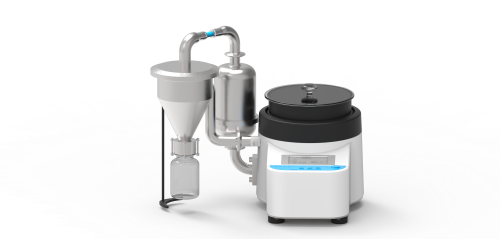

The Navector small negative pressure airflow sieve is specifically designed for sieving low-density, easily agglomerated fine particles. It solves problems like agglomeration, mesh blinding, and static adsorption during powder sieving. Utilizing aerodynamic sieving, it prevents agglomeration and ensures good sample dispersion. It is compatible with test sieves having apertures of 10 microns and above. The sieving process is gentle and requires no non-mechanical sieving accessories. Average sieving time is 2-3 minutes. It can be connected to a manually adjustable industrial suction device or optionally equipped with an automatic suction device, providing continuous airflow to ensure repeatability of the sieving process.

II. Working Principle

A vacuum cleaner is connected to the sieving instrument, creating negative pressure within its inner chamber. Due to the pressure difference, strong airflow forms at the nozzle. This airflow jets onto the sieve mesh surface and is then drawn through the sieve apertures. Consequently, samples smaller than the aperture size follow the airflow through the apertures into the vacuum cleaner or cyclone collector. The airflow helps disperse particles and cleans the sieve mesh.

III. Equipment Advantages

IV. Equipment Parameters

|

Parameter |

Value/Specification |

|

Usable Particle Size Range |

3 μm ~ 4mm |

|

Max. Load |

100g |

|

Max. Levels |

1 (Level 2 requires cyclone collector) |

|

Nozzle Speed |

5-55 RPM |

|

Time Setting |

0-99 minutes |

|

Extraction Pressure |

2000-9999 Pa / 20-99 mbar / 0.3-1.45 psi |

|

Storable Parameter Sets |

9+ Quick Start |

|

Compatible Sieve Diameter |

φ200 mm / φ203 mm |

|

Sieve Stack Height |

25 mm / 50 mm |

|

Dimensions (W x D x H) |

460 x 288 x 305 mm |

V. Application Fields

Pharmaceutical materials, Chemicals, Chemicals, Plastics, Rubber, Minerals, Powder coatings, Pigments, Toners, Ceramics, Food, etc.