In the field of precision screening, the screening of low-density, easily agglomerated fine particles has always been a challenge in the industry. Navector (Shanghai) Screening Technology Co., Ltd. has introduced the small negative pressure airflow sieve, which provides a new solution for the screening analysis of fine particles with its advanced aerodynamic screening technology.

Ⅰ.Principle Introduction

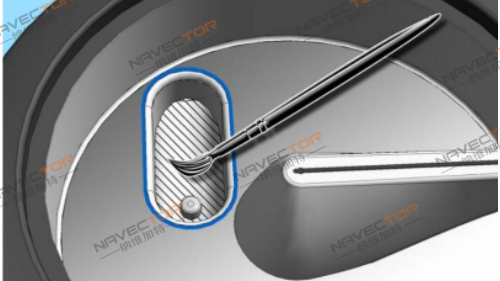

The core principle of the small negative pressure airflow sieve is to create a negative pressure environment by connecting a vacuum cleaner to the screening instrument. Under negative pressure, the nozzle generates a strong airflow that is sprayed onto the screen surface. The airflow penetrates through the screen apertures, carrying particles smaller than the mesh size into the vacuum cleaner or cyclone separator. This process not only effectively disperses the particles, preventing agglomeration, but also cleans the screen to ensure smooth operation during the screening process.

Ⅱ.Equipment Advantages

Ⅲ.Application Areas

The small negative pressure airflow sieve is widely used in industries such as pharmaceuticals, chemicals, plastics, rubber, minerals, and food, effectively screening fine particles, preventing agglomeration, and ensuring product quality. In the pharmaceutical, chemical, and food industries, it is used for the precise screening of raw materials and additives; in the plastics industry, it helps improve particle uniformity and screening efficiency. This equipment is an ideal choice for the analysis of various fine particle screening applications.

As industrial production continues to demand more refined management, the small negative pressure airflow sieve, with its efficient screening performance, flexible operation, and reliable repeatability, has become an important tool for fine particle screening analysis. Navector (Shanghai) Screening Technology Co., Ltd. is dedicated to providing more efficient, safe, and precise screening solutions to help industries improve production efficiency and product quality.