Screen Selection Guide: Key Factors Affecting Screening Precision

2025/12/23

In industrial screening, the screen is a core component that directly impacts screening efficiency, production productivity, and product quality. Different materials and application scenarios have varying requirements for screens. Choosing the right screen is crucial to ensure screening precision and production efficiency. A scientifically and rationally selected screen can not only improve screening performance but also extend the screen's service life and ensure stable production.

Ⅰ. Screen Selection Guide: Scientific Matching for Precise Screening

-

Screen Material and Surface Treatment

The material of the screen determines its durability, strength, and applicability. Common screen materials include stainless steel, polyester, nylon, etc. Stainless steel screens, with their excellent corrosion resistance and high-temperature tolerance, are suitable for industries like chemicals and pharmaceuticals that require high screening standards. Polyester screens are commonly used in applications with lower requirements, offering better cost-effectiveness.

Additionally, the surface treatment of the screen (such as electroplating, spraying, heat treatment, etc.) significantly impacts its wear resistance and anti-aging properties.

-

Mesh Count and Aperture Size

The mesh count determines the range of particle sizes that can be screened. The higher the mesh count, the smaller the aperture, and the higher the screening precision. However, an excessively high mesh count can cause screen blockage. Therefore, the mesh count should be chosen based on the material's particle size distribution. Both excessively high and low mesh counts can negatively affect the screening effect.

The uniformity of the screen’s aperture size is also crucial. Uneven aperture sizes can result in uneven material screening, impacting the final product's quality.

-

Screen Tension and Tensioning

The tension of the screen directly affects its stability during operation. Proper tension effectively prevents the screen from deforming due to vibration or material impact, ensuring precise screening. Too loose or too tight screen tension can affect the screening result, so it is necessary to adjust the tension based on specific screening equipment and working conditions.

-

Material Properties and Screen Compatibility

The properties of materials, such as particle size, shape, density, and viscosity, significantly affect the choice of screen. For fine powders and wet materials, a screen with smaller apertures and high wear resistance is required; for viscous materials, a screen material with better anti-adhesion properties and larger apertures is needed to prevent material buildup or screen blockage.

-

Vibration Type and Screen Compatibility

The choice of screen should match the vibration type of the equipment. Different vibration types (such as linear vibration, rotary vibration, swing vibration, etc.) will impact the screen’s load and screening efficiency differently. Therefore, selecting the appropriate screen to match the vibration type of the equipment can enhance screening efficiency and precision.

Ⅱ. Navector Screens: Designed for Customized Solutions

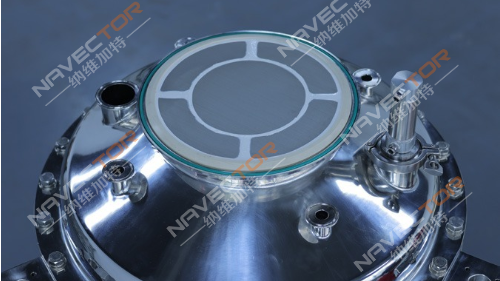

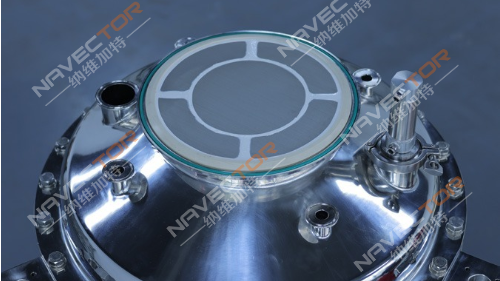

As a leader in the screening technology industry, Navector (Shanghai) Screening Technology Co., Ltd. focuses on providing high-quality screening solutions. Our screen products feature the following significant characteristics to meet the screening needs of various industrial sectors:

-

High-Quality Materials and Durability

Navector screens are made of premium stainless steel and high-strength materials, effectively coping with harsh industrial environments. Our screen materials are heat-resistant and corrosion-resistant, suitable for industries such as chemicals, pharmaceuticals, and food, ensuring long-term stable use and extending equipment lifespan.

-

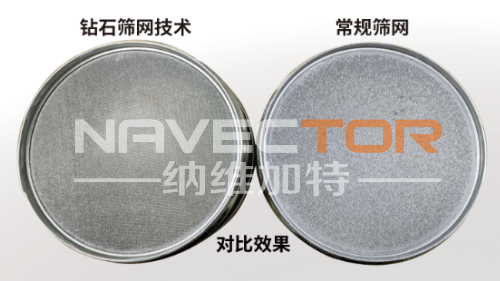

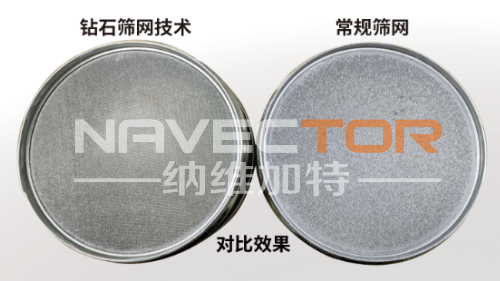

Precise Aperture and Uniform Screening

Navector screens are manufactured with precision, featuring uniform and accurate aperture sizes to achieve high-precision screening. Whether for fine powder screening or large particle separation, our screens ensure high screening efficiency and product quality.

-

Multiple Vibration Mode Compatibility

Depending on the requirements of different vibration equipment, Navector screens offer various specifications and vibration mode compatibility. Whether it's linear vibration, rotary vibration, or swing vibration, our screens can match with different equipment to provide stable screening performance.

-

Wear Resistance and Anti-Blockage

To meet the demands of high-frequency and high-load screening, Navector screens focus on wear resistance and anti-blockage properties. Our screen designs take into account material flowability and particle shape, effectively preventing screen blockage and ensuring continuous and efficient screening.

Based on customer needs, Navector provides customized screen solutions. Whether it's special materials, specific aperture sizes, or screening requirements for unique materials, we offer personalized designs to ensure the optimization of screening results.

As a leader in screening technology, Navector provides high-quality screen products and professional screening solutions, backed by years of technical expertise and rich industry experience. If you have any questions or needs regarding screen selection, feel free to contact Navector at any time.