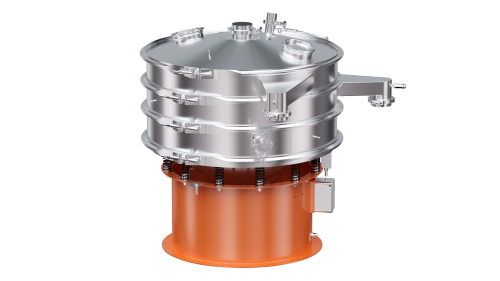

In industrial production, the screening of fine materials is a common yet complex challenge. Especially when dealing with materials that are highly adhesive, prone to agglomeration, highly electrostatic, fine-grained, or dense, traditional vibrating screens often fail to meet production demands. The Navector Ultrasonic Vibrating Screen, with its advanced technological design, successfully overcomes these screening challenges, greatly improving both screening efficiency and mesh-cleaning performance.

Ⅰ. Breaking Traditional Screening Limitations: Effectively Suppressing Mesh Blocking Factors

During the screening process, materials often exhibit adhesion, friction, settling, and wedging behaviors—particularly prominent when handling fine, moist, or electrostatically sensitive powders. The Navector Ultrasonic Vibrating Screen, through optimized vibration frequency and mesh design, effectively suppresses these issues, significantly enhancing screening efficiency.

The core breakthrough of the Navector Ultrasonic Vibrating Screen lies in its application of a high-frequency, low-amplitude ultrasonic vibration wave over the screen mesh—an innovation that fundamentally changes traditional screening dynamics.

Ⅱ. Tackling Difficult-to-Screen Materials: Separation of Adhesive and Agglomerative Powders

The Navector Ultrasonic Vibrating Screen is specifically designed for challenging materials, showing exceptional screening performance when dealing with high adhesion, agglomeration, or static-related problems. Through innovative engineering, the screen effectively addresses the following challenges:

Ⅲ. Improving Screening Efficiency and Equipment Durability: Precision Control and Efficient Mesh Cleaning

Beyond solving difficult screening issues, the Navector Ultrasonic Vibrating Screen also excels in enhancing efficiency and extending equipment lifespan. Its advanced design and technological optimizations make the screening process more stable and efficient, reducing maintenance and replacement frequency.

From adhesion to static charge, from wedging to agglomeration—every long-standing challenge in the screening industry has found a solution through Navector’s ultrasonic technology. By fundamentally resolving mesh-blocking issues, the Navector Ultrasonic Vibrating Screen transforms the screening process from a cost burden into a productivity engine.

Navector is not content with merely providing equipment—it is dedicated to delivering customized screening solutions tailored to each client’s unique needs. In an era where fine powder screening demands are increasingly stringent, Navector continues to set new standards for the industry through technological innovation.