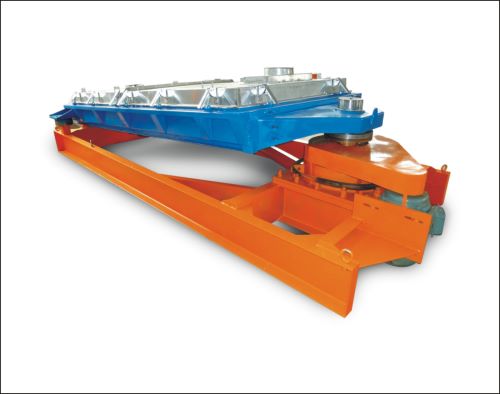

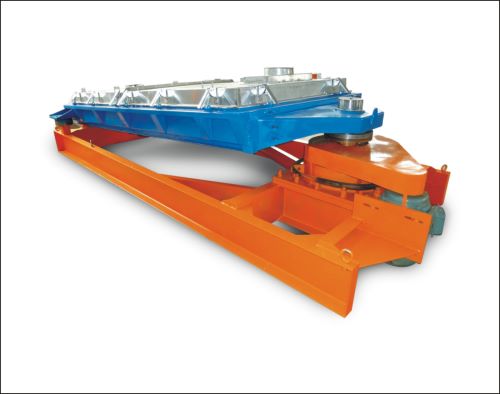

Imitating Hand Screening, Mass Production: How the NPFS Fine Suspended Sifter Achieves Both High Precision and High Capacity

2025/09/28

In traditional industrial screening, efficiency and precision seem always difficult to reconcile. Increasing throughput often means sacrificing screening accuracy, and pursuing high precision usually forces one to accept reduced capacity. This contradiction is particularly evident in many industries such as chemical, food, pharmaceutical, and mining.

The NPFS series fine suspended sifter from Navector (Shanghai) Screening Technology Co., Ltd. adopts the principle of imitating hand screening, successfully solving this problem.

I. Biomimetic Design: The Scientific Principles Behind Low-Speed Screening

-

Low-speed horizontal gyration → Gradient trajectory design

At the feed end, material is initially thrown onto the screen surface in a nearly horizontal circular trajectory, similar to how a person shakes a sieve by hand; the material is gently spread. As it moves forward, the trajectory gradually changes into an ellipse, and finally at the discharge end becomes close to linear back-and-forth motion. This transformation of trajectory increases the "residence time" of material on the screen, while enabling the recognition and separation of particle sizes under gradual change.

-

Stratification and thinning

When people hand-screen, they adjust force and angle so that material is first spread thin and layered. The motion mode of NPFS causes material on the screen to be quickly thinned and layered (with distinct high and low strata), giving smaller particles more chance to contact and pass through the screen mesh, while larger particles or aggregates are pulled or tumbled by gravity and by changes in trajectory, being retained or moved toward the discharge end.

-

Gentle and stable contact

Unlike conventional high-speed vibrating screens whose violent jumps can cause impact breakage or dust from the material, NPFS operates with low frequency, low jumping, and gentle contact. This method reduces material breakage, ensures that well-shaped particles are preserved, and allows the pressure and impact load on the screen surface to be evenly distributed, which is also better for durability.

-

Improved screening precision thanks to extended trajectory

In hand screening, one naturally extends the screening time so that fine particles and impurities can be “screened over” multiple times rather than quickly dumped. The design of NPFS lengthens the material’s movement path inside the machine—moving from circular to elliptical then to linear—so that material travels longer distance and time on the screen surface, allowing fine particles sufficient “probing,” thereby greatly enhancing screening precision.

II. Meticulous Craftsmanship: Clever Design Achieving Efficient Screening

-

Adapting to complex shapes and irregular surfaces: for irregular, easy-agglomerating, or rough-surfaced particles, the hand-screen imitation lets them roll and rotate at different angles and amplitudes, making screening more thorough and reducing the chance of “getting stuck” or misclassification.

-

Minimizing damage to material: low frequency and gentle motion reduce crushing and wear, which is especially critical for fragile materials (e.g. in pharmaceuticals, chemicals, food, etc.).

-

Reducing mesh clogging and cleaning frequency: the motion trajectory and material layering design ensure that material is continuously dispersed across the screen surface; small particles pass through quickly, while large particles and aggregates are moved evenly. In combination with mesh-cleaning structures (such as elastic balls, etc.), this can effectively prevent mesh holes from getting blocked.

-

Improving product consistency and grading accuracy: because small particles can be more thoroughly discriminated and filtered, the discharged particles are more uniform in size, which is hugely beneficial for downstream processing and final product quality standards.

The “imitating hand screening principle” is not merely a marketing slogan; it is the core technology of the NPFS fine suspended sifter. It is tightly integrated with its trajectory design, low-frequency gentle motion, thinning and layering, and stable contact mechanisms, enabling the equipment to deliver screening effects “as delicate as human hands” even under large capacity, heavy load industrial environments.Any screening problem can be addressed by contacting Navector.