(From left to right: vibrating screen, swinging screen)

As a core component of screening equipment, the performance and service life of the screen mesh directly impact production efficiency and costs. As usage time increases, the wear of the screen mesh gradually intensifies, not only leading to a decline in screening efficiency but also potentially severely affecting the normal operation of the production line.

Navector (Shanghai) Screening Technology Co., Ltd., with its deep industry accumulation and continuous technological innovation, is committed to helping clients effectively extend the service life of screen meshes through a series of scientific and systematic solutions, ensuring stable, efficient, and controllable production processes.

Ⅰ. The Dangers of Screen Mesh Wear

As screen mesh wear intensifies, both screening accuracy and efficiency significantly decrease, leading to ineffective material separation or incomplete screening, which directly affects product quality and production efficiency. Wear of the screen mesh can also cause frequent equipment failures, increase maintenance costs, and lead to production line stoppages, resulting in production delays and profit losses. Moreover, excessively worn screen meshes may damage other equipment components, further increasing the maintenance burden and overall operational costs. Therefore, addressing screen mesh wear promptly is crucial for improving production efficiency and reducing costs.

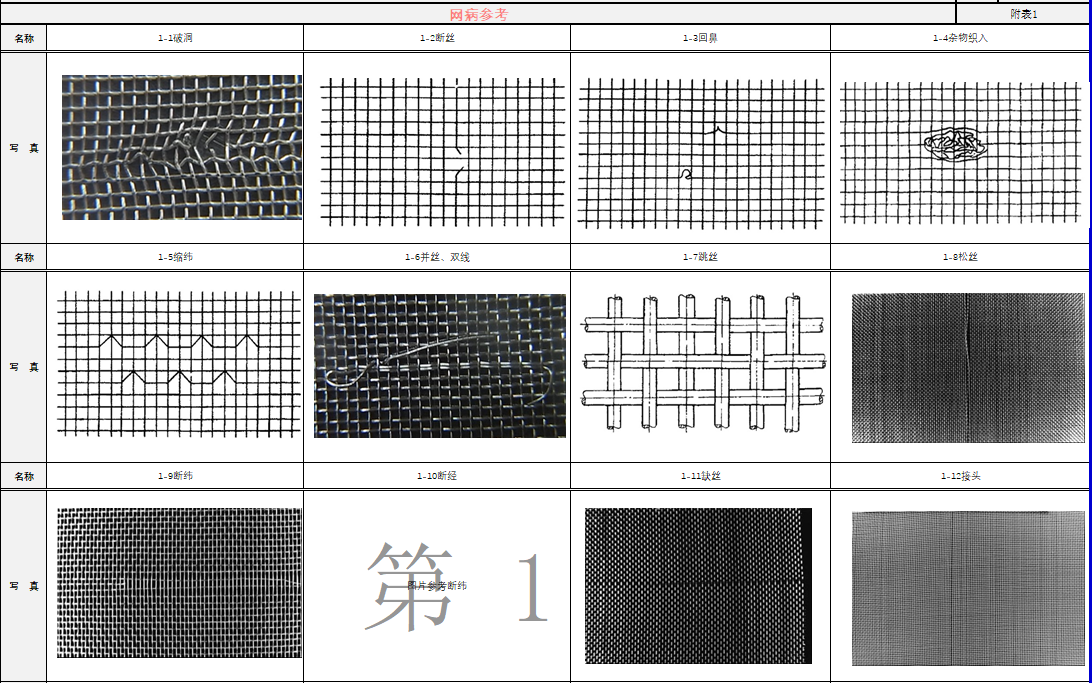

Damaged mesh reference

Ⅱ. The Root Causes of Screen Mesh Damage

To effectively extend the life of screen meshes, it is essential to accurately identify the root causes of damage. Based on numerous engineering case analyses, Navector categorizes the causes of screen mesh damage into the following types:

Screen clogging

Ⅲ. In-Depth Analysis of Navector's Screen Mesh Technology

Navector approaches the challenge of screen mesh longevity with a systematic mindset, offering a complete solution from core technology applications to customized configurations.

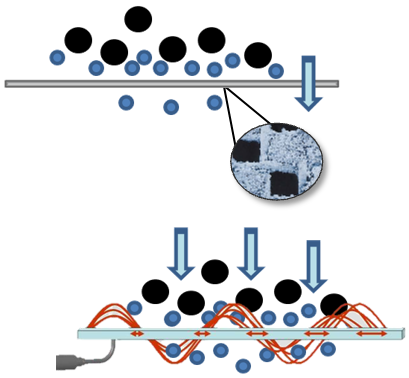

Navector Ultrasonic System

The tension of the screen under repeated use in a high-frequency environment

Navector provides full lifecycle support services to ensure that screening equipment operates efficiently at all times. From equipment selection, installation, and debugging to regular technical support and maintenance, we offer a one-stop solution to ensure that the screen mesh remains in optimal working condition. Based on specific client needs, Navector's technical team also provides personalized screening solutions to ensure equipment adapts to different working conditions. Additionally, we offer regular screen mesh inspection and replacement services to effectively extend the mesh's service life and minimize production line downtime.

Navector (Shanghai) Screening Technology Co., Ltd. will continue to drive technological innovation, always focusing on customer value, and is dedicated to becoming a reliable partner for global clients in enhancing screening efficiency and optimizing production operations.