With the rapid development of high-end manufacturing sectors such as lithium batteries, powder coatings, and fine chemicals, there are increasing demands for product particle size, uniformity, and cleanliness. Especially when particle sizes reach the micron level, materials are prone to static electricity and aggregation. Traditional screening equipment often struggles to meet the four core demands of screening efficiency, operational stability, production capacity, and cleanliness and safety.

Navector (Shanghai) Screening Technology Co., Ltd. deeply understands this industry trend and challenge. Since its establishment in 2005, it has focused on the innovative development of screening technology, providing leading, reliable, and efficient ultrafine powder screening solutions for customers.

In practical production and screening processes, the demand for small particles and ultrafine powders is increasing, but this has also exposed several issues, including but not limited to:

Powder particles tend to generate static electricity during the screening process, causing them to stick together and form agglomerates. These agglomerates are much larger than the mesh aperture and therefore cannot pass through the screen.

The electrostatic issue leads to agglomeration and requires rework.

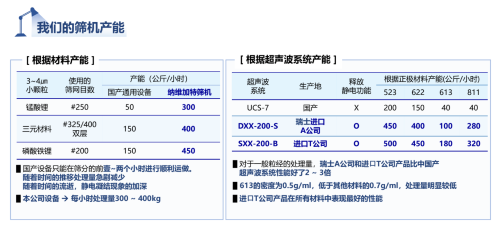

Navector’s small particle screening machine for the lithium battery industry is specifically designed for the sector. This equipment combines advanced ultrasonic screening technology with 3D vibration and swing vibration modes to efficiently prevent mesh blockage and particle embedding from 50 to 635 mesh, significantly enhancing screening capacity and extending the lifespan of the mesh.

Navector's small particle screening machine is equipped with leading ultrasonic screening technology. This technology effectively prevents fine particles from electrostatically adhering to the mesh surface through high-frequency vibrations from ultrasonic waves, thus reducing blockage and particle embedding issues.

Resonance Excitation Concept (Conventional Concept)

Resonance Frequency Concept (Our Approach)

The equipment integrates 3D vibration and swing vibration modes, precisely controlling vibration frequency and amplitude to achieve even distribution of materials and efficient screening. This vibration mode effectively solves the issue of static particle agglomeration, making the screening process smoother.

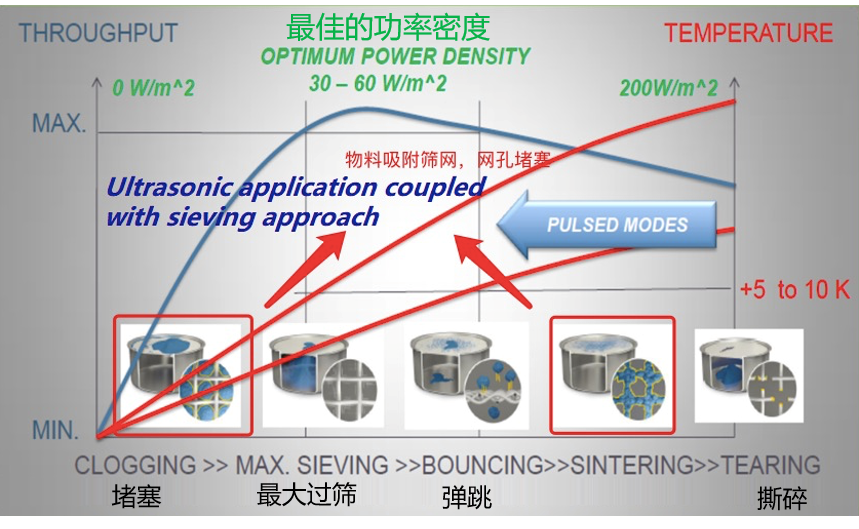

Graph of Processing Capacity and Power Density

Solving the Clogging Problem Caused by Electrostatic Adsorption on the Screen

By adopting Navector's innovative technology, customers have not only effectively reduced static electricity and mesh blockage issues but also significantly improved production efficiency in several aspects. Furthermore, the design of the equipment effectively extends the mesh lifespan, reducing the frequency of replacements and lowering maintenance and downtime costs.

Maintaining Screen Tension under Repeated Use in a High-Frequency Environment

Stability and efficiency ensure continuous production and high-precision material screening, especially when dealing with ultrafine particles, meeting strict screening requirements. Navector's screening machines are widely used in sectors such as new energy battery materials, powder coatings, and photovoltaic silicon powder, helping enterprises enhance production efficiency and reduce costs.

As technology continues to evolve, Navector will remain committed to providing high-efficiency, precise screening equipment for more industries, driving further industrial upgrades.