The design concept of the equipment originates from the process requirements of solar front silver paste manufacturers. As a patented product, its core function is solving the separation challenges of high-concentration viscous materials unmanageable by traditional screening technologies.

Although silver paste filtration represents a niche segment in the screening industry, NaviGoat actively innovates high-end screening solutions for customers.

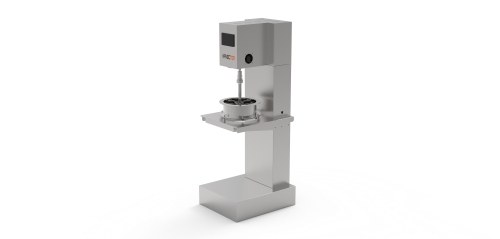

I. Working Principle

Based on Germany’s advanced filtration technology for high-value, high-viscosity coatings, the system integrates ultrasonic vibration to achieve filtration down to -8μm particle size under atmospheric pressure, even with ultra-high solid content.

II. Equipment Advantages

III. Technical Parameters

|

Parameter |

Specification |

|

Dimensions (H×W×D) |

1500 × 500 × 600 mm |

|

Weight |

80 kg |

|

Power Supply |

AC 220V ± 20%, 50Hz |

|

Rated Power |

600 W |

|

Main Motor |

250 W, 0–175 rpm |

|

Lifting Motor |

25 W, 20 mm/s vertical speed |

|

Ultrasonic System |

30 kHz, 50 W |

|

Throughput Capacity |

10–30 kg/h |

IV. Application Scope

Primarily designed for high-viscosity slurries, with core implementation in solar front silver paste filtration.