Vibrotary Separator

We are leaders in fine mesh separation technology with over 10 years experience of providing solutions in more than 100 countries .We are committed to understanding and meeting your specific needs by close collaboration, design innovation and the provision of facilities for testing your materials on Navector vibro sifter equipment.

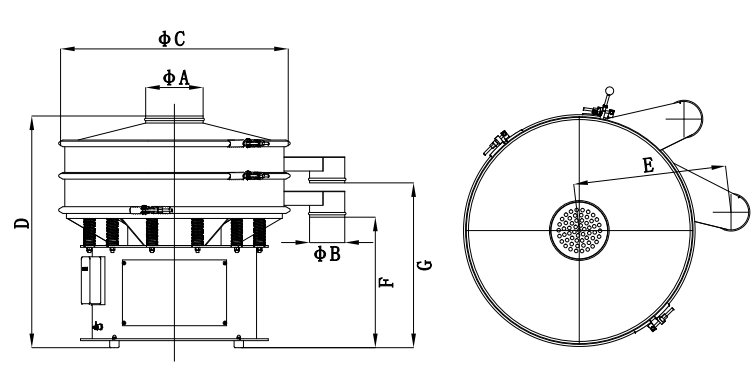

Vibrotary Separator

The total function of this type of Vibratory screener is to seperate the dry materials into particles of different diameters, or extract solid from liquid. The operator can set the speed and movement direction of screen, providing the best processing capacity and screening efficiency for any products. As a kind of vibratory separator equipment, Navector vibro sifter can process whatever the material is wet or dry, heavy or light or coarse or fine.

- Separate particles up to 635 mesh ScreenScreen Screen Screen Screen Screen

- At most four-layer screens ScreenScreen Screen Screen Screen Screen Screen Screen

- Easy design and less power consumption ScreenScreen Screen Screen

- Various type of screens : L V P ScreenScreen Screen Screen Screen Screen Screen Screen

- Make particles separation easier, Screen Screen Screen Screen

- Lower power consumption, lower maintenance. Screen Screen Screen

- The high performance Navector Vibrating Screen is engineered to handle screening problems by customers throughout the processing industries.

Data sheet:

| Type | 400 | 600 | 800 | 1000 | 1200 | 1500 |

| A | 145 | 145 | 195 | 245 | 245 | 245 |

| B | 100 | 100 | 100 | 150 | 170 | 200 |

| C | 400 | 600 | 800 | 970 | 1170 | 1470 |

| D | 700 | 900 | 940 | 990 | 1075 | 1200 |

| E | 302 | 442 | 557 | 651 | 780 | 938 |

| F | 370 | 480 | 505 | 555 | 610 | 675 |

| G | 524 | 630 | 655 | 705 | 760 | 840 |

| Power(KW) | 0.2 | 0.35 | 0.6 | 1.1 | 1.1 | 1.5 |

| Excitation Force(KN) | 4 | 7 | 13 | 20 | 20 | 32 |

Improves your product quality

Increases your productivity Screen Screen Screen Screen

Operator friendly Screen ScreenScreen Screen Screen

Reduces your costs Screen ScreenScreen Screen Screen