Navector's small particle screening equipment, designed specifically for the lithium battery materials industry, provides innovative solutions to the industry's stringent requirements for consistent powder size distribution, purity, efficiency, and equipment durability.

Utilizing innovative anti-blocking technology, agglomeration breaking capabilities, precise classification performance, and stable low-temperature operation, this equipment significantly improves screening efficiency, accuracy, and production capacity, extending the life of core consumables (screens), ensuring product quality and production continuity, and providing strong support for high-quality, large-scale, and efficient production of lithium battery materials.

I. Major Issues Facing the Current Market:

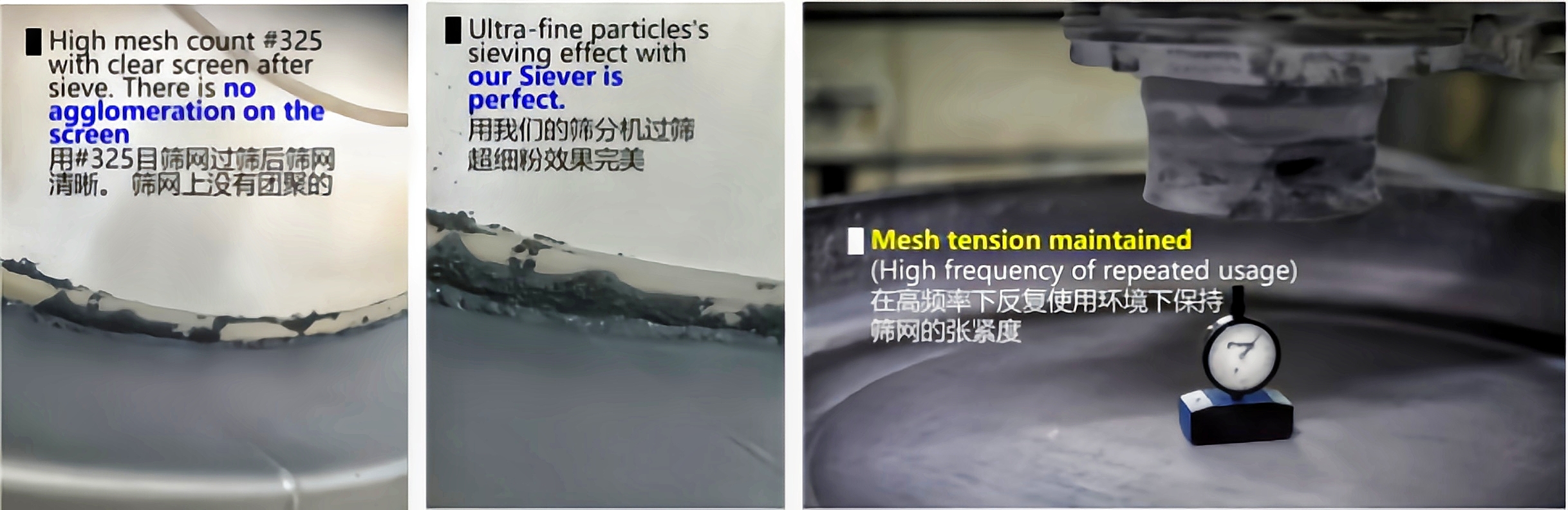

Very short lifespan and imperfect screen tensioning affect screening efficiency

Particle agglomeration leads to ineffective screening and filtration efficiency

Current domestic technology is limited to screening capabilities of 3-5 microns and cannot reach 3 microns or below to meet future demand.

Ⅱ.Advantages of Navector Equipment:

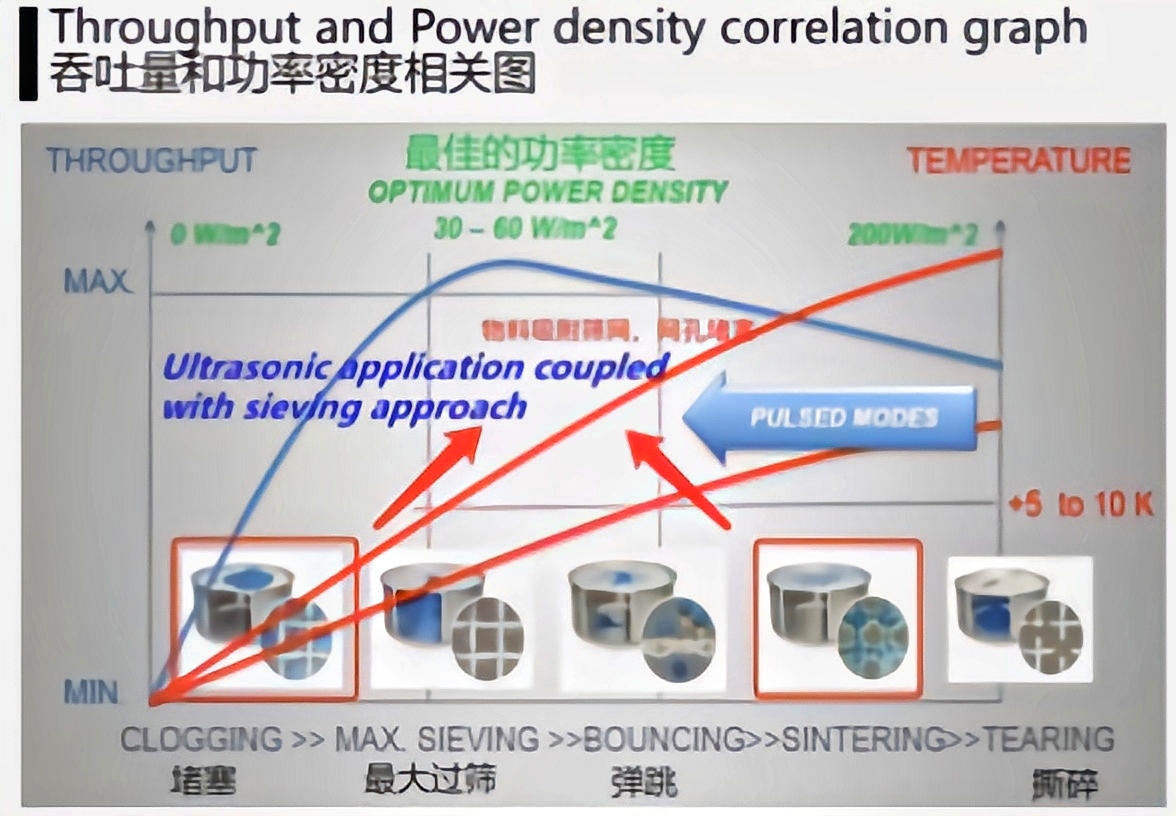

The unique ultrasonic screening system instantly removes fine powder adsorption from the back of the screen, preventing clogging of the 50-635 mesh and mesh impaction by similar particles, thereby extending the life of the valuable screen. This ensures production continuity and accurate material distribution.

Targeting the high static electricity and easy agglomeration of lithium battery materials (such as lithium carbonate and graphite), Navector Equipment achieves a breakthrough through ultrasonic technology and anti-static structural design. This technology truly solves the screening challenges of strong adsorption, high static electricity, easy agglomeration, and low specific gravity, accelerating the separation of agglomerates, thereby increasing screening capacity and reducing the number of large particles.

It can clearly separate fine particles of similar diameters without changing the material's properties, making it particularly suitable for new materials.

The system's excellent compatibility ensures continuous operation without increasing the operating temperature, making it particularly suitable for materials requiring controlled temperature rise.

Ⅲ. Project Case Display