In industrial production, screening often faces the dual challenges of space limitations and equipment adaptability. Navector has addressed this pain point with the innovative development of the NCS series of Compact Sieve. With its disruptive low-profile design, flexible mobility, and adaptability to multiple scenarios, it redefines the industrial value of screening equipment.

I. Compact Design Unleashes Space Potential

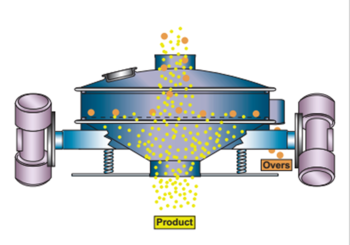

The NCS series inline screener breaks through the height limitations of traditional screening machines. Its flat design makes the unit significantly lower than comparable products in the industry. Its compact size allows for easy integration into production line spaces, storage areas, and even laboratory environments, eliminating the need for additional space modifications. Screened material is discharged directly downward from the center of the screener, facilitating integration into production lines. For example, in food processing plants, the equipment can be integrated directly alongside the production line, seamlessly integrating raw material pretreatment and screening.

II. Versatile Screening Meets All-Scenario Needs

Leveraging dual-motor balanced drive technology, the NCS series offers adjustable screening modes, adapting to pellet feed sizes ranging from 1 micron to 20 mm. With a screening accuracy of 100 μm, it is widely used in a variety of industries, including chemicals, granular explosives, flour, starch, laundry detergent, breadcrumbs, metal powders, additives, and non-minerals. It is particularly useful in the food industry, where it can remove hard foreign matter and other impurities, preventing accidents and ensuring efficient and stable screening.

III. Equipment Advantages Overview:

Navector's NCS series Compact Sieve are designed with the concept of "minimizing space and maximizing efficiency." With their low profile, flexible mobility, and adaptability to multiple scenarios, they are the preferred screening solution for industries such as food, pharmaceuticals, and new energy. Choosing Navector means choosing more than just a piece of equipment; it means choosing a comprehensive solution that extends from screening process optimization to comprehensive service.