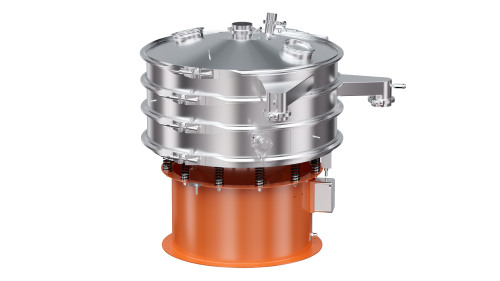

Thousands of Navector NHI Series vibrating screens are in operation worldwide, proving their efficiency, reliability, and wide adaptability.

The NHI Series vibrating screens can screen and filter a wide range of materials, from heavy and light powders, coarse and fine granules, wet and dry materials, to slurries and liquids. Operators can configure the material flow rate and speed across the screen, adapting the screen to meet the screening needs of various industries.

The NHI Series vibrating screens can be equipped with an ultrasonic system, specifically designed to address the screening and grading of difficult-to-screen fine powders in various industrial production applications, while also enabling clear separation of particle sizes.

I. Working Principle

The kinetic energy generated by the motor causes the machine to vibrate, passing the material through a single or multiple screen layers, separating it into various particle size groups or separating impurities from a slurry. During the screening process, the material rolls on the screen, allowing it to pass more smoothly through the screen.

The ultrasonic screen cleaning system superimposes a high-frequency, low-amplitude ultrasonic vibration wave on the screen. Ultrafine powders are subjected to the tremendous ultrasonic acceleration, keeping the material on the screen surface in a constant state of suspension. This suppresses factors such as adhesion, friction, flattening, and wedging, improving screening and cleaning efficiency. It also addresses screening challenges such as strong adsorption, easy agglomeration, high static electricity, high fineness, high density, and low specific gravity.

II. Equipment Advantages

III. Application Areas

Navector's NHI series vibrating screens can screen and filter a wide variety of materials, including heavy and light powders, coarse and fine particles, dry and wet materials, slurries, and liquids. They are used in a variety of industries, including chemicals, food, pharmaceuticals, lithium batteries, metal powders, and abrasives.