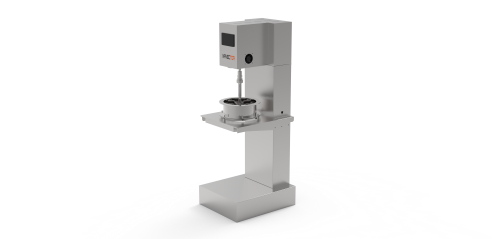

In the solar industry, the screening and filtration of silver paste is a critical step in ensuring the quality of the final product. Traditional screening equipment often faces issues like insufficient precision and low efficiency when handling high-viscosity silver paste. To address this challenge, Navector (Shanghai) Screening Technology Co., Ltd. has designed a silver paste filtration screen specifically for the front-side silver paste in solar cells. A core feature of this equipment is its high-precision filtration capability.

Ⅰ. Ultra-High Precision Filtration Ensures Silver Paste Purity

The biggest characteristic of the silver paste filtration screen is its exceptional high-precision filtration ability. In traditional filtration methods, high-viscosity silver paste often leads to incomplete filtration, with impurities and fine particles being left behind, affecting product quality. The silver paste filtration screen uses advanced German technology for filtering high-viscosity coatings and combines an ultrasonic system, enabling precise filtration even under normal pressure conditions, even with a high solid content.

This high-precision filtration ensures that small impurities and particles in the silver paste are completely removed, greatly enhancing the purity of the silver paste and, in turn, improving the performance of solar cells. Whether it’s removing particles or ensuring the quality of the silver paste, this fine filtration capability is unmatched by other equipment.

Ⅱ. Practical Benefits of High Precision

Ⅲ. Designed for High-Viscosity Materials

The silver paste filtration screen is not just a traditional screening device; it is a specialized filtration device designed for high-viscosity materials. In the processing of high-viscosity silver paste, which contains a high solid content, conventional equipment often cannot meet the requirements for effective screening. The ultrasonic technology and unique design of the silver paste filtration screen ensure high precision and efficiency when processing such viscous materials, making sure that the screening effect is not affected by the material’s viscosity.

The high-precision filtration of the silver paste filtration screen is its greatest core advantage and a key factor in its success in the solar industry. By combining ultrasonic technology with advanced coating filtration principles, the silver paste filtration screen maintains excellent filtration precision when processing high-viscosity silver paste, ensuring product quality and reducing production costs. It provides a perfect solution for the precise screening of high-viscosity materials and is the ideal equipment for solar cell manufacturers to produce high-quality silver paste.

From fine screening to precise screening, technological breakthroughs have no limits. Navector’s innovation continues to move forward.