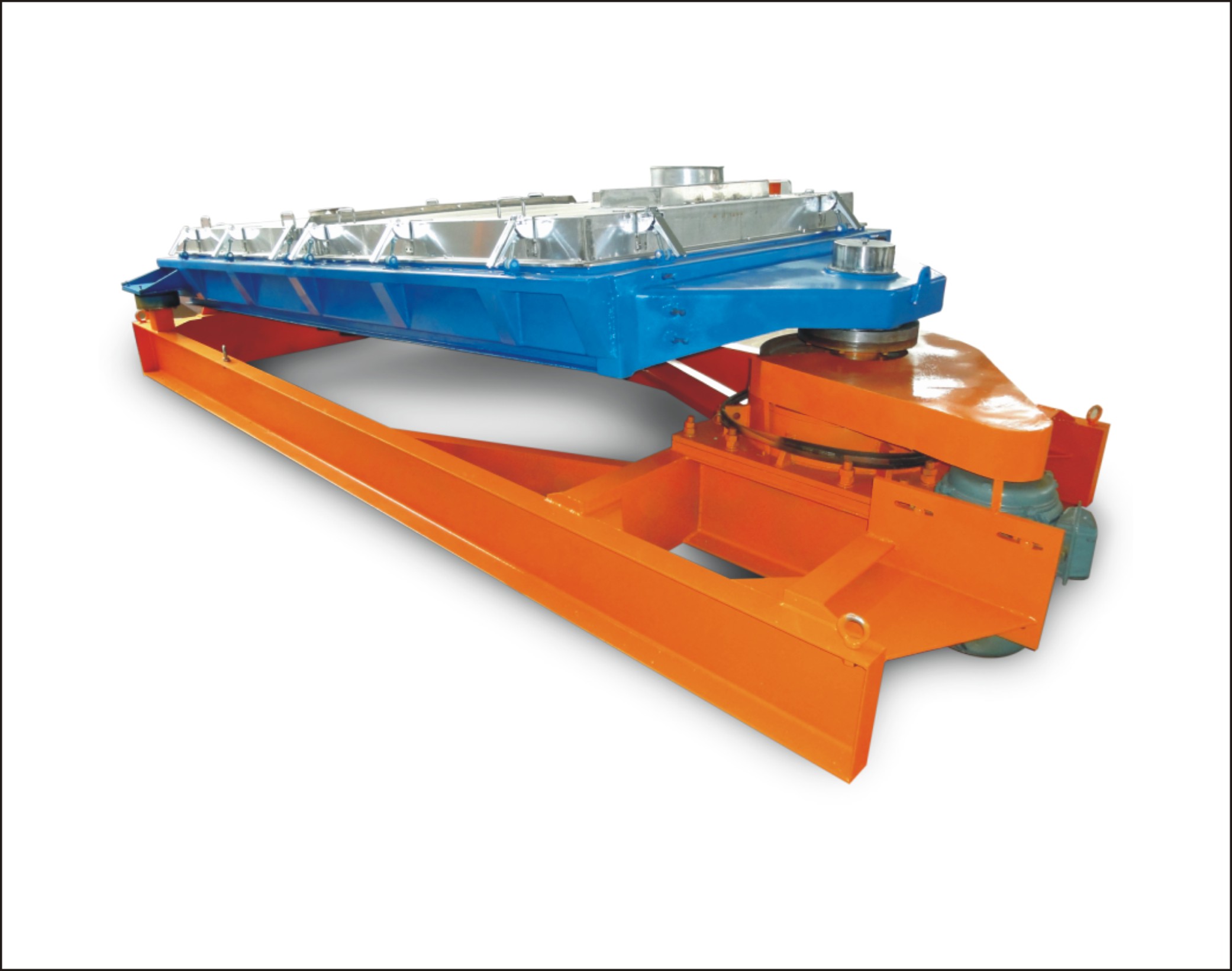

The NPFS series suspension screen is a large-scale screening equipment specifically designed for particle material screening. With a large screening area, it meets the screening requirements for spherical, strip-shaped, flake-shaped, columnar, fragile, and irregular particle materials in industrial-scale mass production.

Ⅰ. Working Principle

The manual screening principle is applied, with a low-speed horizontal rotary motion. The material’s movement trajectory in the suspension screen begins as a horizontal circular motion at the feed end. It gradually turns into an elliptical motion along the length direction, and eventually becomes an almost reciprocating linear motion at the discharge end. This extended screening trajectory ensures high-precision screening.

Ⅱ. Advantages of the Equipment

Ⅲ. Application Fields

The NPFS series suspension screen is widely used in industries such as chemicals, food, sugar manufacturing, expanded clay, mining, metallurgy, feed, pharmaceuticals, building materials, mining, grain, paper-making, and many others, for high-capacity particle screening. The maximum production capacity of a single unit can reach 365 tons per hour.