In powder processing and fine particle screening, screen blinding is a common challenge that significantly affects production efficiency. Easy agglomeration of particles, high electrostatic attraction, and blockage of screen apertures all lead to reduced screening efficiency and extended production cycles. Navector (Shanghai) Screening Technology Co., Ltd. has long been committed to the research and development of screening technologies, among which the airflow sieve demonstrates significant advantages in addressing screen blinding issues during fine powder screening.

I. Principle Overview

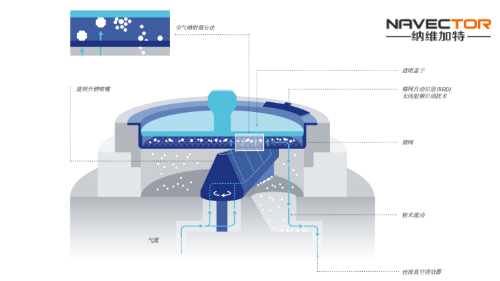

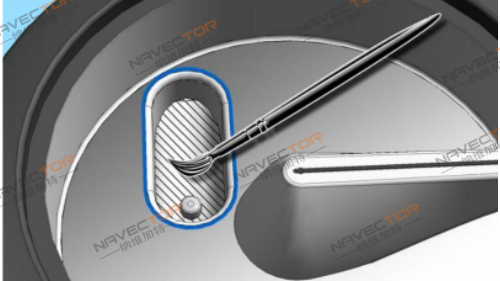

The airflow sieve utilizes aerodynamic forces for screening. The equipment can be connected to an air extraction device to create a negative-pressure airflow within the screening chamber. Airflow is injected through nozzles onto the screen surface, placing the powder in a dynamic air environment. Materials smaller than the screen aperture pass through the mesh with the airflow into the lower collection unit, while larger particles remain on the screen surface due to airflow action. The core design regulates airflow intensity and jet velocity, allowing fine and easily agglomerated powders to be screened under gentle conditions without the need for mechanical auxiliary devices.

II. Anti-Blinding Advantages

The airflow sieve effectively prevents screen blinding, mainly reflected in the following three aspects:

III. Application Value

The airflow sieve offers practical application value across multiple industries. Its technical characteristics enable outstanding performance when processing fine powders prone to agglomeration. The airflow sieve is suitable for screening operations in pharmaceuticals, chemicals, plastics, rubber, minerals, powder coatings, pigments and colorants, ceramics, food, and other fields.

Screen blinding is a key issue affecting production efficiency and screening stability. By reducing particle agglomeration through aerodynamic principles, keeping screen apertures clean, and enabling adjustable screening parameters, the airflow sieve effectively lowers the risk of blinding. This technology provides a practical and feasible solution for fine powder screening.

With micron-level screening technology at its core, Navector supports industries in achieving efficient screening through customized solutions and a comprehensive service system.