Navector Vibrating Sieve: Technical Principles and Multi-Industry Applications

2026/01/24

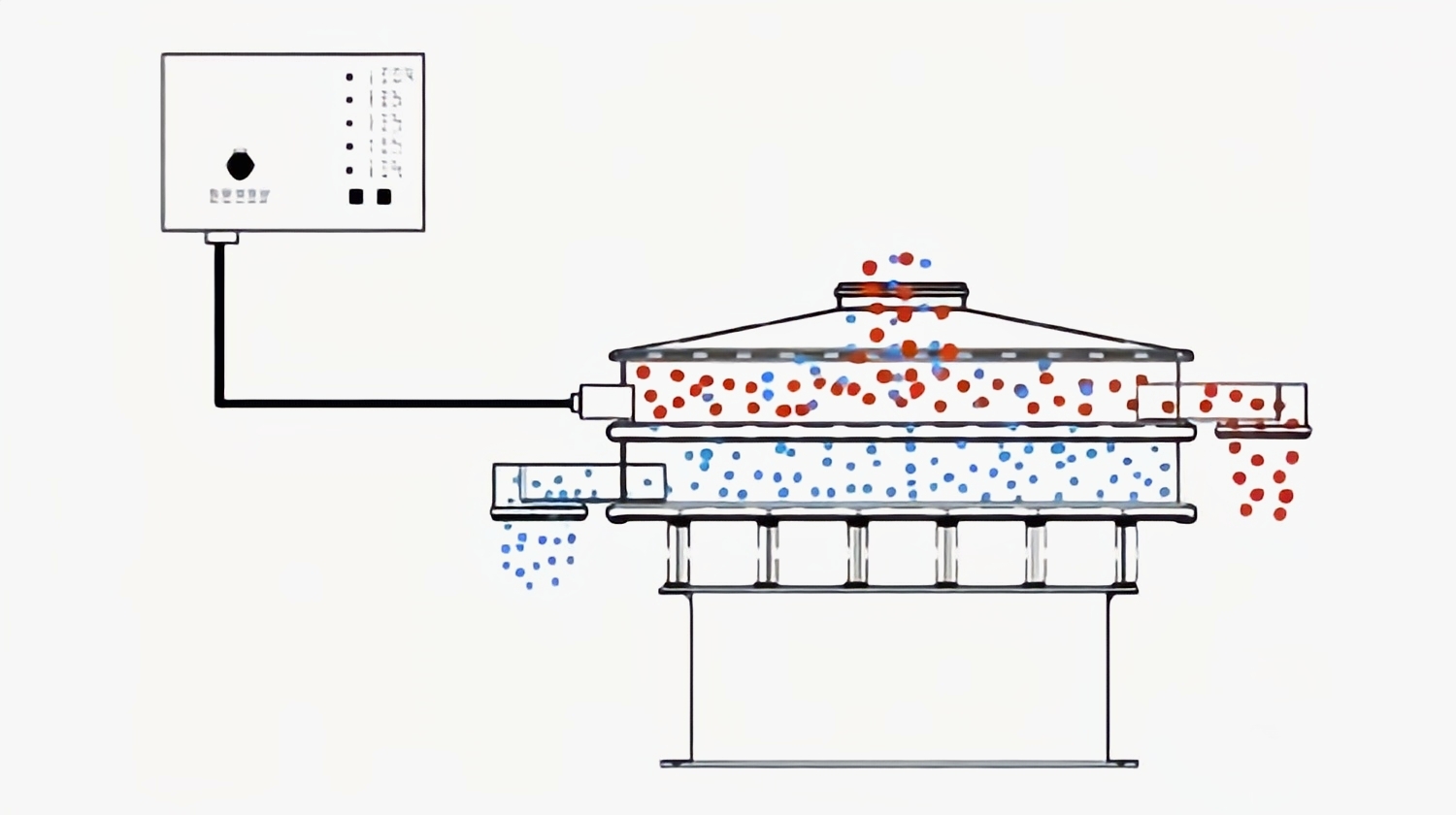

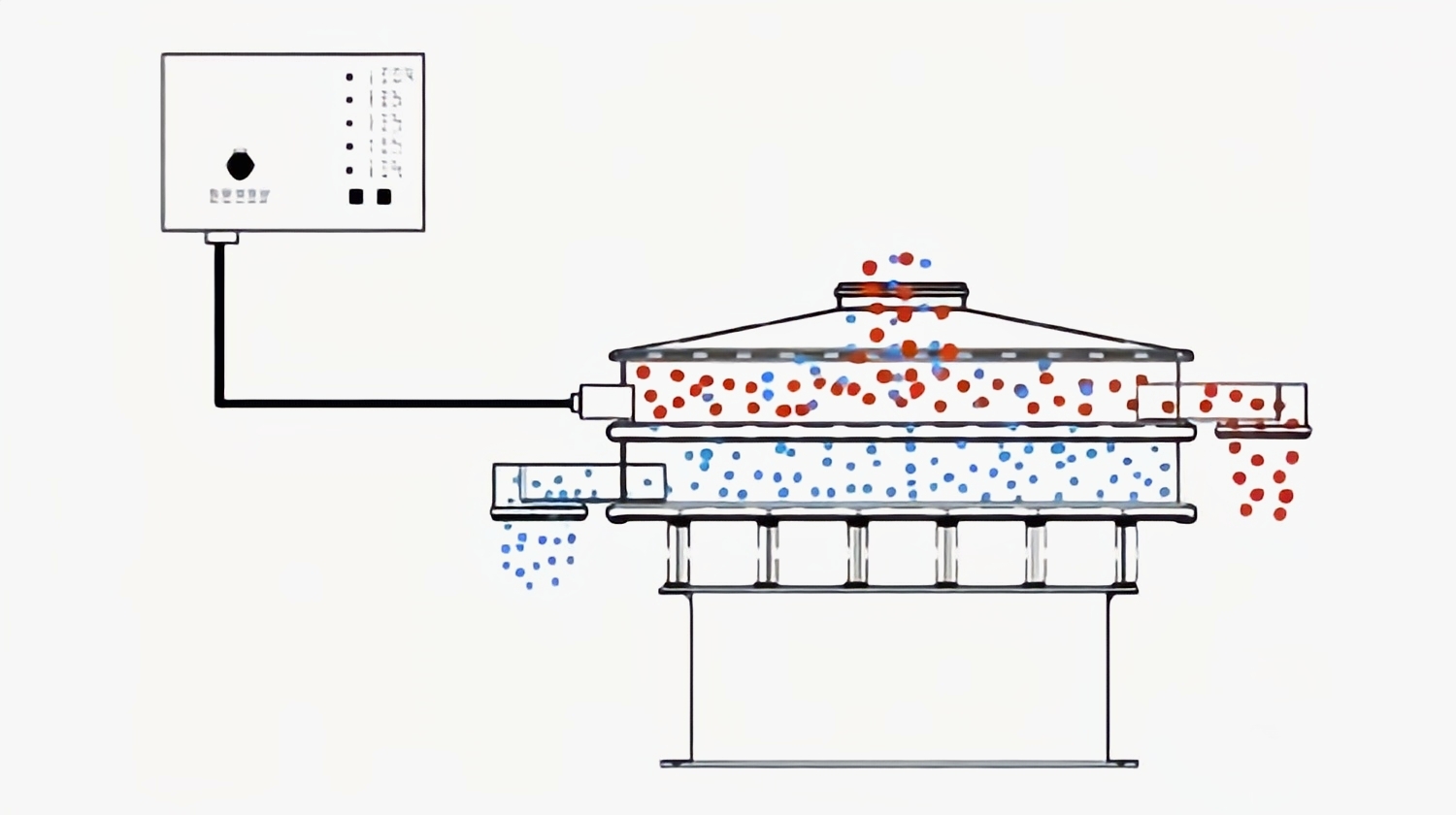

Ⅰ. Working Principle

A high-frequency, low-amplitude ultrasonic vibration wave is superimposed on the sieve surface. Ultra-fine powders receive tremendous ultrasonic acceleration, keeping the material on the sieve in a continuously suspended state. This suppresses factors that cause clogging, such as adhesion, friction, settling, and wedging, thereby improving screening efficiency and mesh cleaning efficiency. It effectively addresses screening challenges involving strong adhesion, easy agglomeration, high static electricity, fine particle size, high density, and low bulk density materials.

Ⅱ. Equipment Advantages

-

Suitable for separating hard-to-screen materials with particle sizes of 10–200 microns; screening fineness can reach up to 400 mesh.

-

Configurable with 1 to 5 layers of sieves with different mesh sizes according to screening requirements.

-

Circumferential discharge outlet design with flexible positioning for convenient production layout.

-

Modular structure for easy disassembly, installation, and cleaning.

-

Simplifies the separation of materials with special properties without altering their characteristics, making it particularly suitable for new materials.

-

Elastic balls or ultrasonic mesh cleaning systems effectively prevent aperture clogging or near-aperture embedding, extending sieve service life.

-

Low and stable operating temperature, no localized overheating, suitable for continuous operation.

-

No special foundation required, with a small installation footprint.

Ⅲ. Application Fields

Used for grading and impurity removal of powder raw materials. Under complex particle size requirements, the equipment achieves efficient and precise separation, ensuring process stability and consistent product quality.

-

Food and Grain Processing Industry

In food processing, material uniformity directly affects the efficiency of subsequent processing steps. The NHI vibrating sieve provides precise particle size control, establishing a quality control foundation for raw material supply.

Uniform particle size and fineness control of pharmaceutical powders are critical to formulation performance. The NHI vibrating sieve, combined with an ultrasonic system, effectively resolves mesh clogging and static adhesion issues, improving consistency in fine powder screening.

-

New Materials and Lithium Battery Industry

In new material development and lithium battery material production, particle size control requirements are both stringent and complex. The NHI series demonstrates high throughput and high stability in handling ultra-fine powders, making it suitable for screening and classification of powder coatings, metal powders, and functional materials.

The NHI series vibrating sieve is suitable for screening and grading abrasives such as silicon carbide, silica micropowder, and glass beads. For abrasive powders with strict particle size distribution requirements and a high tendency for mesh clogging, precise separation and efficient screening can be achieved through multi-layer sieve configurations and ultrasonic mesh cleaning systems, providing reliable support for abrasive product quality control.