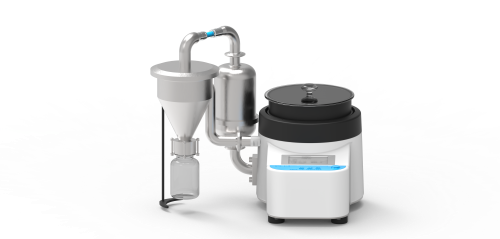

Sieving low-density, easily agglomerated fine particles has always been a technical challenge in quality control processes in the pharmaceutical, chemical, and food industries. Traditional mechanical screening equipment often suffers from low screening efficiency and even mesh clogging when processing 10-micron powders due to electrostatic adsorption and sticky agglomeration between particles, compromising detection accuracy. To address this industry pain point, Navector's small negative pressure airflow sieve, with its innovative aerodynamic design, completely solves the global challenge of ultrafine powder screening.

1. Core Technology: Breakthrough Application of Airflow Dynamics

As a specialized device designed specifically for analytical sieves with pore sizes of 10 microns and larger, its operating principle revolutionizes traditional screening logic:

This design eliminates the need for mechanical vibration or ultrasonic assistance during the screening process, preventing the damage to the sample structure associated with traditional methods. For example, in the pharmaceutical industry, screening of cephalosporin APIs ensures particle morphology is intact, meeting the stringent GMP requirements for drug particle size distribution.

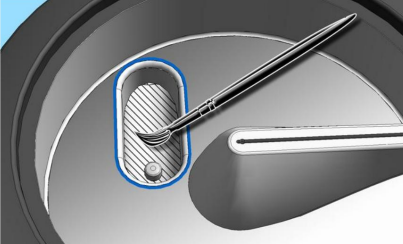

II. Precision Control: Intelligent Screening with Digital Parameters

The revolutionary nature of Navector's small negative pressure airflow screen lies not only in its innovative principle, but also in its fully digitally controlled parameters:

Multi-dimensional adjustable parameters:

Navector's small negative pressure airflow sieving system is ushering in an era of "precision control" for ultrafine powder screening. Its unique airflow screening technology not only solves the problem of agglomeration of low-density particles, but also, through fully digitalized and modular design, provides comprehensive solutions from R&D to mass production for the pharmaceutical, chemical, and food industries.

III. Equipment Advantages

Contact Navector for any screening questions.