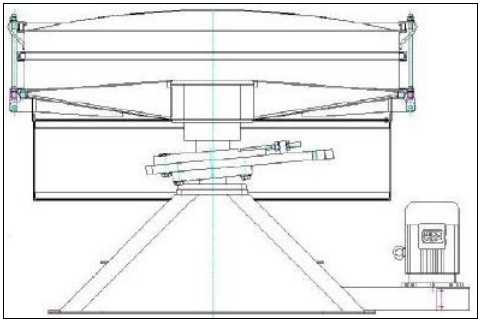

The Navector tumbler screen is specifically designed for industrial applications with large throughput of granular materials and high screening accuracy requirements. It is a high-performance circular screening machine that ensures high efficiency while delivering stable and precise screening results, meeting customers’ dual demands for capacity and quality.

I. Design Principles

The tumbler screen is a type of screening machine evolved from manual screening methods, fully reflecting the combination of screening (circular motion) and tossing (upward throwing motion) during the screening process. By adjusting the radial angle and tangential angle, the amplitudes of screening and tossing can be controlled to achieve optimal screening performance.

By adjusting the radial and tangential angles, the material exhibits a regular involute motion on the screen surface. This motion path allows the material to travel a relatively long distance on a smaller screening area. At the same time, the material rotates on its own axis, enabling full contact with the screen surface and improving screening efficiency.

The tumbler screen is a low-speed mechanical system without resonance, resulting in stable mechanical performance, low noise, long service life, and safer operation. Low-speed operation also makes it suitable for screening delicate materials, minimizing material damage.

II. Screen Cleaning Systems

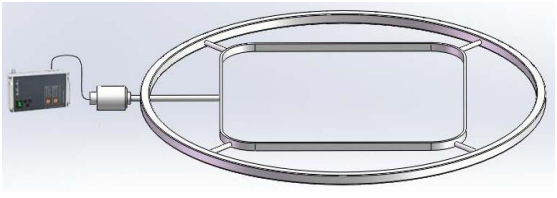

Ultrasonic screen cleaning converts electrical energy into mechanical energy through an ultrasonic power supply and transducer. The ultrasonic vibration is transmitted to the screen surface via the resonance ring in the center of the screen, dislodging materials trapped in the mesh apertures.

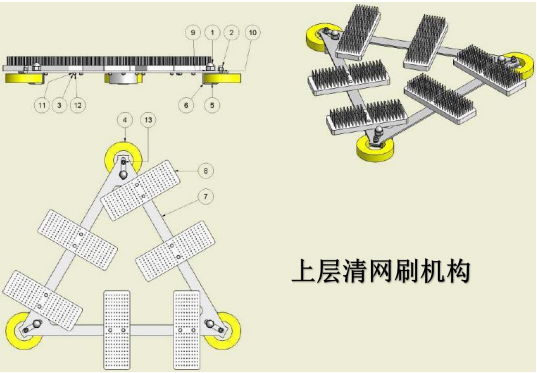

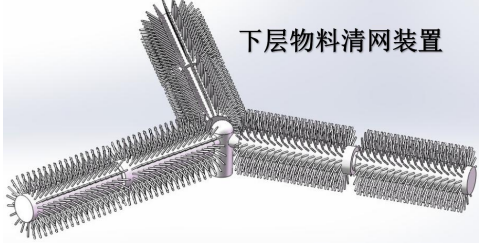

The mechanical brush cleaning system is divided into two types: upper screen surface cleaning and lower screen surface cleaning. The brushes themselves are used to sweep away materials that block the mesh openings.

III. Analysis and Solutions for Common Problems

(1) Excessive Oversize Material Discharge?

1.Whether the proportion of oversize material matches the user’s material composition

2.Whether the correct screen mesh has been selected

3.Excessive feeding rate

4.Whether ultrasonic or other screen cleaning devices are operating properly

5.Whether the material has static electricity or moisture

6.Positive pressure inside the screening machine

1.Adjust the material proportion

2.Select the correct screen mesh

3.Reduce the feeding rate

4.Inspect and repair the ultrasonic system

5.Connect antistatic devices and adjust the material condition

6.Release the positive pressure gas

(2) Abnormal Noise from the Screening Machine?

1.Manually rotate the mechanical rotating parts to check whether the bearings are damaged

2.Check the tension of the pulleys and belts

3.Check whether the upper frame of the screening machine is securely fastened

4.Check whether the motor is damaged

5.Check whether there are foreign objects inside the screening machine

1.Replace the bearings and carry out proper maintenance

2.Replace the belt and adjust belt tension

3.Evenly tighten the upper and lower connecting threaded rod nuts

4.Inspect and repair the motor

5.Remove foreign objects

(3) Abnormal Jumping of the Screening Machine?

1.Open the swing body protective door to check whether the four upper and lower bolts are tightened

2.Whether the anchor bolts are loose

3.Whether the upper locking nuts of the screening machine are loose

1.Retighten the connecting bolts to 50–70 Nm

2.Secure the anchor bolts

3.Tighten the upper and lower connections

4.Check whether the tension springs are damaged

5.Check whether the threaded rod nuts were correctly installed during machine disassembly

6.Replace the tension springs

7.Reassemble correctly

(4) Ultrasonic System Stops Working or Overheats?

1.Loose connection of the ultrasonic transducer

2.Damage to the ultrasonic transducer or power supply

3.Broken data cable

1.Tighten the ultrasonic transducer with a wrench

2.Inspect and repair the power supply or transducer

3.Replace the data cable

(5) Abnormal Screen Mesh Breakage?

1.Excessive feeding rate

2.Presence of sharp, large particles in the material that can cut the screen

3.Discharge rate too slow

4.Presence of foreign objects contacting the screen surface

1.Reduce the feeding rate

2.Install a protective screen to remove sharp, large particles

3.Adjust and increase the discharge speed of the screening machine

4.Remove or relocate objects contacting the screen surface