Breaking Through Bottlenecks, Reshaping Circularity: Navector Innovates 3D Printing Powder Recycling System

2025/09/05

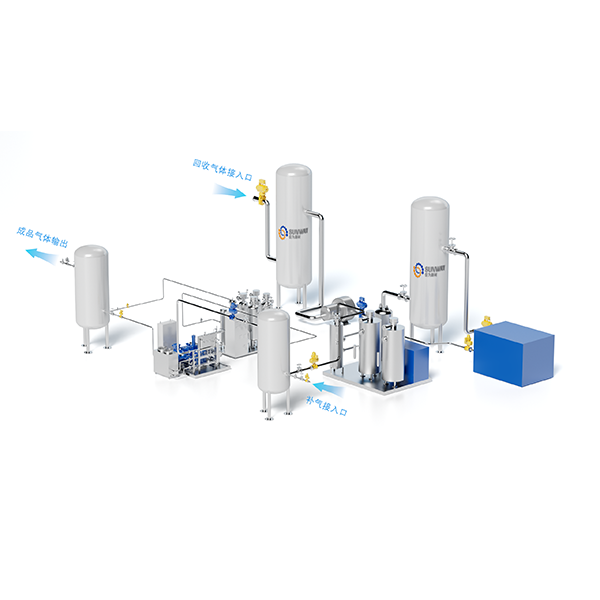

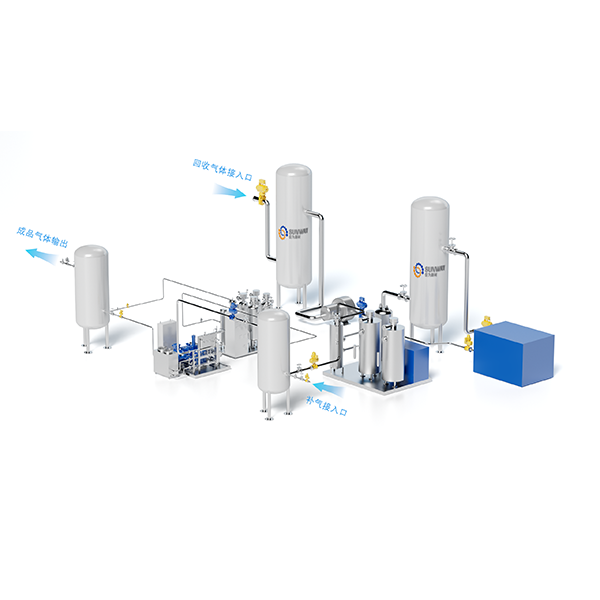

Navector's independently developed 3D printing additive recycling system, protected by a fully enclosed inert gas atmosphere, enables efficient and safe screening and recycling of metal powder, resolving the industry's long-standing challenges of material oxidation and contamination.

In the cutting-edge field of metal powder 3D printing (laser forming manufacturing), "powder recycling" remains a key bottleneck hindering cost reduction and quality improvement. Shanghai Navigate Screening Technology Co., Ltd., leveraging its deep understanding of precision separation processes, has developed a 3D printing additive recycling system. This patented device fills a gap and provides a disruptive solution for the safe recycling and efficient reuse of metal powder.

Ⅰ. Powder Management Challenges in Metal 3D Printing

Metal powder, as a core raw material for 3D printing, faces two major challenges in actual production:

-

Powder contamination: Metal condensate is generated during laser forming. When mixed with unused powder, it directly reduces the purity of the powder. Continued use can seriously affect the precision of printed parts and even render the product scrapped

-

Oxidation waste: Reactive metal powders and fine particles such as aluminum and titanium are highly susceptible to oxidation when exposed to the environment. These factors not only make them unreusable, but also pose safety risks due to the accumulation of oxidized powder, resulting in significant waste of raw materials

Ⅱ.Navector's Patented Solution

The NMS system achieves efficient and safe recycling through the following methods:

-

Real-time suction and screening: Dissipated metal powder and condensate during the printing process are continuously drawn into the screening equipment

-

Inert gas closed circulation: The entire screening and recovery process is conducted in a closed inert atmosphere, ensuring a low-oxygen environment and effectively preventing oxidation of fine powders

-

Pure powder recycling: The separated metal powder is directly fed into the powder feeder and recycled back into the printing system for reuse

Ⅲ.Empowering the 3D Printing Industry

The NMS series system is designed to fully reflect cutting-edge needs and offers the following significant advantages:

-

Fully enclosed inert gas protection: Ensures low-oxygen explosion protection, ensuring operational and equipment safety

-

Large particle separation: Effectively filters out metal condensate, providing a safer and more stable operating environment for printing equipment

-

Continuous recycling: Automated separation and refilling eliminate the need for human intervention, maintaining printing continuity

-

Automatic refill mechanism: Reduces operational risks, prevents human contact with fine powders, and improves safety

-

Highly efficient and material-saving: Enables metal powder recycling, reduces material waste, and improves economic benefits

-

Simple disassembly, cleaning, and maintenance: Reduces downtime and facilitates daily operations

-

No powder escape, low-noise operation: The closed-loop system operates quietly and is environmentally friendly

The NMS series 3D printing additive recycling system is a safe, efficient, and material-saving solution for the metal powder 3D printing industry. It integrates four key advantages: manufacturing continuity, safety, material reuse, and easy maintenance and management, helping labs and production lines improve additive material utilization efficiency and printing stability.