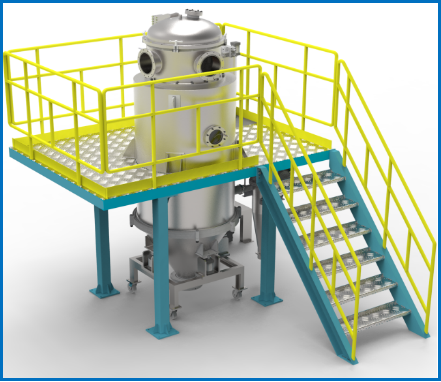

NHL VIGA 05 Vacuum Melting Gas Atomization System adopts the closely coupled fine atomization technology with independent intellectual property rights of Navector Laboratory, and can obtain micron-sized spherical metal powder particles under rapid cooling at 105-106K/S.

The system is specially designed for scientific research and is used for the production of small batches (1-5kg) of micron-sized spherical powder products such as stainless steel, copper alloy, aluminum-based alloy, and high-temperature alloy. The produced powder has low oxygen content, uniform particle distribution, and fine powder. It has the characteristics of high spherical, and the production process can meet the requirements of safety, environmental protection and energy saving.

The system adopts a modular design and can provide multi-functional optional modules such as high temperature and high pressure to meet the research and development needs of various alloy powders of different scales.

|

Crucible Form |

Medium frequency induction heating |

|

Crucible Capacity |

1L (1-5kg, calculated by steel) |

|

Nozzle Type |

Supersonic straight tube type (close coupling) |

|

Atomization Rate |

Typically 1-3kg/min (based on steel) |

|

Powder Particle Distribution (D50) |

10-100um |

|

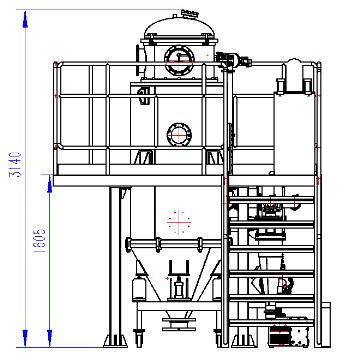

Melting Chamber |

Top opening, water-cooled, 304 stainless steel |

|

Atomizing Chamber |

304 stainless steel, internally polished, optional water-cooled |

|

Powder Processing |

High-efficiency cyclone separation, HEPA filter system |

|

Equipment Power |

60KVA, 3-Phase, 50-60Hz |

|

Water Cooling Demand |

Approx. 70L/min, 5 Bar |

|

Atomization Gas |

Argon/Nitrogen/Helium; <6kg/min; <64Bar |

|

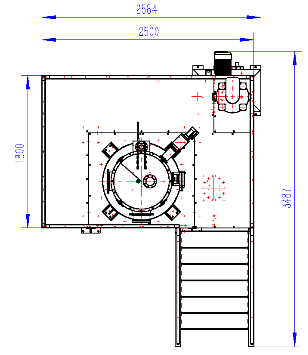

Equipment Dimension |

2.6m×3.5m×3.2m |

|

Equipment Weight |

Approx. 5 Ton |